Buying a Power Jointer

By Joshua Farnsworth

What is a Power Jointer?

A power jointer is used to flatten a face and edge of a rough board during the milling process. Like a jointer plane, the power jointer’s long, flat cast iron bed (like the plane’s long, flat sole) removes high spots progressively, until the face of the board is completely flat. It is really gratifying to see the beautiful fresh wood appear as the rough, dirty wood disappears.

After obtaining a flat face, I turn the rough board on edge, with the freshly flattened face against the side fence. Because the fence is set perfectly square to the bed, I achieve a perfectly square face and edge. After jointing the board, I take it to the thickness planer, and then table saw. I’ll talk about those machines below.

Flattening the face and squaring the edge can be done with handplanes and other hand tools (you can see how to do it in my video & article here). But it does take a lot longer to do. I still use the hand tool method when I have boards that are too wide for my power jointer, but I often prefer milling up my lumber with power tools, and then cutting the joints with hand tools.

Below I’ll discuss several features to consider before buying a power jointer:

1. Jointer Cutterhead Style?

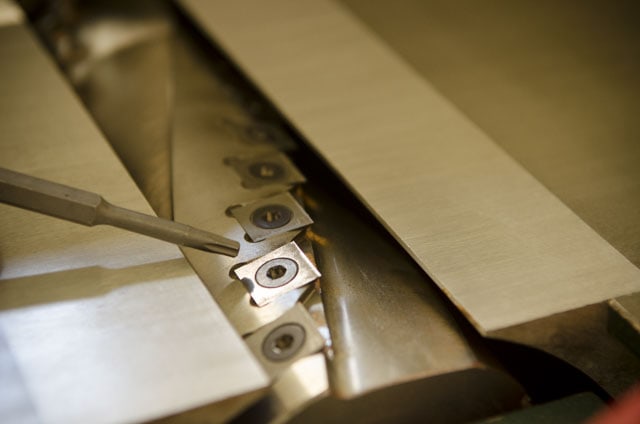

To me, the type of cutterhead that comes on a power jointer is one of the most important considerations, so I’ll begin with this first. The first jointers I used and owned had three straight knives attached to the rotating shaft. This style of cutter was so frustrating. In addition to leaving bad tearout, if the blades dulled or got a nick (from dirt, knots, or embedded nails), the removal, sharpening, and re-setting of the blades was extremely frustrating. The three knives had to be set at the same, perfect height, which required gadgets like magnetic jigs or dial indicators. Acquiring the flu seemed more favorable than having to set jointer & planer knives. But nobody knew any better, until Spiral cutterheads and Helical cutterheads came along. Bless whomever invented spiral cutterheads! This was a major step forward for power tools like jointers and thickness planers, because three straight blades were replaced with dozens of small, square carbide inserts. And carbide stays sharp much longer than steel.

The blades move around the cutterhead in a spiral or helical pattern, which greatly reduces tearout compared with the old style blades, even on figured wood. Even going against the grain! On my modern jointer, which features a spiral cutterhead, I can mill up figured wood, like curly maple, with hardly any tearout at all. Machine marks are typically all that I have to deal with now.

And replacing chipped or dull blades? That problem is now nearly non-existent too. Each small, square carbide blade has four sides, so if you have a nicked blade, all you have to do is loosen the set screw, rotate the single blade, and tighten it down again. It takes only a few seconds. Compare that with having to replace a whole jointer knife.

And I find that the carbide blades stay sharp much longer than the old straight jointer blades. Under heavy use, I get about 1 year before I start noticing a dulling of the carbide blades. So that’s 4+ years before you need to buy more blades (under heavy use). Most quality new jointers come with spiral cutterheads, but if it doesn’t, the upgrade is well worth the expense.

What’s the difference between spiral cutterheads and helical cutterheads?

Spiral cutterheads align each insert carbide blade facing the wood straight on. Helical cutterheads, on the other hand, have the carbide blades set at a skewed angle for more of a shearing cut. In all of the tests that I’ve read, the spiral cutterheads and helical cutterheads don’t really show any difference in surface quality, except on wood with the most difficult grain. In those cases the helical cutterheads gave slightly better results, but overall both styles left almost no wood tearout.

I own a jointer and thickness planer with “spiral” cutterheads, and they both leave very nice surfaces, even on highly figured woods. In my opinion, as long as the manufacturer says “spiral cutterhead”, “helical cutterhead”, “shear-cutting head”, or “Byrd cutterhead” it should work just fine.

2. What width of Power Jointer Should I Buy?

So what size should you look for in a jointer? Jointers come in various sizes, from the enormous and scary vintage cast iron jointers to the small, budget jointers with a tiny 4-inch wide bed. I’ve stood next to a 24-inch wide antique wood jointer, and while I loved the thought of jointing very wide boards, I realized that it didn’t fit within my comfort zone. It was very similar to the monstrous jointer in this video:

Unless you are using a newer jointer of this size, with safety features such as power feeders, it is just plain nerve racking to use a huge 24-inch antique jointer. And on the opposite side of the spectrum, I’ve owned and used many small 6-inch jointers before, and felt quite limited. It’s not to say that you can’t make beautiful furniture with a 6-inch jointer, but it just takes more time and effort.

My preference is a jointer with a bed 8-inches wide or wider. An 8-inch wide jointer allows me to joint wider boards than a 6-inch jointer, and 8-inch jointers usually come with longer infeed and outfeed beds, adding more support to the lumber. And 8-inch jointers are usually affordable enough for hobbyist woodworking shops. The price usually jumps up when moving up to a 12-inch or 16-inch jointer.

3. Length & Style of the Jointer Bed and Fence?

Jointer Bed Length: The length of a jointer bed is another important consideration when buying a power jointer. The longer the bed (which is made up of an infeed table and an outfeed table) the more stability you’ll have when flattening and jointing a board. Somewhere in the range of 80-inches is a popular length. Some woodworkers don’t have much room in their shop, so they opt for jointers with shorter beds, around 60-inches. A shorter bed should work fine for many situations, but doesn’t offer quite as much support.

Parallelogram jointer bed vs. Dovetailed Ways bed: Over time the beds of power jointers may go out of parallel (like a twisted board), and the sag must be adjusted. The less-expensive jointers use sliding “dovetail ways” which have to be shimmed back into parallel. This is a more difficult method for bringing the jointer beds back to parallel. An upgraded style of jointer is one with a “parallelogram” bed, which makes parallel adjusting easier, as all four bed corners can be independently adjusted. Here are two videos that show both methods of adjustment so you can determine if it is worth it for you to spend more money for a parallelogram bed (the second video shows my jointer):

Infeed table adjustment: The depth of cut on a power jointer is controlled by lowering and raising the infeed table. Raising and lowering the bed is accomplished by two different types of adjusters. The most common is the lever adjuster. The “upgrade” is a hand wheel adjuster. After unlocking the infeed table, the lever adjuster is simply lifted up or down to the correct height. The wheel adjuster gives a finer and easier adjustment. My jointer has a lever adjustment, but it would be more convenient to have the wheel adjustment.

Fence adjustment: To get a perfect 90 degree angle between the jointer bed and fence, an adjustment must be made on the fence. Rack and pinion fence adjustment (with a wheel) is an upgrade over the manual lever adjustment. I have a lever adjusted fence, which is quite a bit more difficult to adjust than rack and pinion, but it isn’t a huge problem since I don’t move my fence too often. But if you plan on moving your fence in and out (for cutting rabbets, for example, or for jointing at an angle) then you may want to consider the jointer that I mention below, which comes with a rack and pinion adjuster.

Blade guard cover: A spring-loaded guard swings out of the way when a board is pushed over the cutterhead, and it swings back in place with springs after you’ve finished pushing the board over the cutterhead. Most major brands have good blade cover guards, but over time the little spring looses its tightness and should be replaced to maintain safety.

4. Should I Buy a Normal Dedicated Jointer or a Jointer/Thickness Planer Combo?

For smaller workshop spaces, some woodworkers have to make a compromise. A combination jointer/planer is one example of this type of compromise. While a combo jointer/planer is often cheaper and takes up less space, it may not be as specialized as having a separate jointer and planer. Unless you buy one of the higher-end models mentioned below. The short beds on many combo machines don’t allow for as much support, and while you would get a wider jointer than normal (12-inches wide is common) the planer would be the same size, and 12-inches is more narrow than many planers, like my 15-inch planer. But if you don’t plan on planing boards wider than what you joint, this isn’t an issue. And a 16-inch jointer/planer combo would handle almost any project you may have.

A combo machine also requires switching the machine back and forth between jointer and thickness planer. If you’ve got a shop where multiple people will be jointing and planing at the same time, then you’d want two separate machines. But most people don’t need to use a jointer and thickness planer at the same time. So the inconvenience would just come down to switching the machine from jointer mode to planer mode. The higher-end jointer/planer combos (like Felder) make this simple and very quick. At the end of the day, if limited finances and space are more important than having the flexibility of jointing and planing independently, then a jointer/planer combo may work for you.

I must say, if you have a huge budget for woodworking machines, then some combo machines are excellent. My friend recommends his Felder AD 941 16-inch jointer/planer machine. The beds are just as long (or longer) than many jointers, and he can joint and plane boards up to 16-inches wide, which is astounding. Felder also makes a 20-inch machine (the Felder AD 951). These machines have incredible tolerances and accuracy. The 16-inch Felder runs around $11,500, but it’s still less expensive than buying a separate 16-inch jointer and large thickness planer from companies like Grizzly. And the quality is higher than Grizzly. You can see some of the Felder woodworking machines here. Minimax jointer / planer combos are also high-end. Here’s a Felder video to make you drool:

Felder also makes the “Hammer” series of jointer/planer combos that are more than enough for most woodworkers, and less than half the cost of the Felder line. You can see them here. And here are some comparably very affordable hobbyist jointer/planer combo woodworking machines that you can check out at:

- Rikon 12” Planer / Jointer at Rockler Woodworking

- Jet® 12” Planer/Jointer Combo w/Helical Head at Rockler Woodworking

- JET 708476 Model JJP-12HH 12-Inch Planer/Jointer with Helical Cutterhead at Amazon

- Grizzly G0634Z 12-inch Planer/Jointer with Spiral Cutter head at Amazon

5. Power Considerations

When buying a jointer, pay attention to the power that it uses. Most woodworking shops use single-phase power, while big commercial shops use three-phase power. A woodworking machine motor made for three-phase power will not work in most home workshops. If you want to learn more (i.e. if you’re a science nerd) then feel free to read this article: “Difference between Single Phase and Three Phase AC Power Supply“.

Also, if you use normal single-phase electricity, be sure that you’ve had an electrician install a 220V electrical outlet near where your jointer will reside, as most larger power jointers use 220V single-phase power. Some smaller jointers may use normal household 110V electrical outlets.

An easy to see and reach power switch is also an important feature to look at when buying a power jointer. Having a big “STOP” button is very important in the event of an emergency.

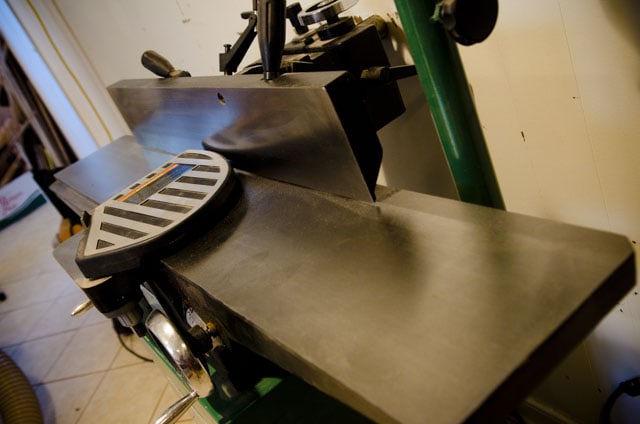

My Power Jointer

About five years ago I upgraded to an 8-inch jointer. It is the Grizzly G0490X 8″ jointer. I chose this jointer after much research. It checked off all the boxes I needed at the time, including the price point. It features a spiral cutterhead, an 8-inch parallelogram bed, it has a long table (76-3/8inch), and a powerful 3HP motor. It also had won a tool review test in a prominent woodworking magazine. I have pushed thousands of board feet of lumber through this jointer, and it has worked good. It retails for around $1,600 (with shipping).

After five years, I have noticed a few drawbacks:

- I find that I use a lot of boards wider than 8-inches, so I feel limited by the width. This probably won’t be a problem for you, but I prefer making traditional furniture with wide boards.

- The spring guard isn’t my favorite, as the spring has worn out and won’t swing back after passing a board over the cutterhead. However, I probably just need to order a new spring from Grizzly, so this isn’t a big problem.

- The heavy cast iron fence is tough to square up with the handle feature. A rack & pinion system (like the Grizzly model below) would work better, or the more advanced fence systems of higher-end machines, like the Felder jointers.

- After a couple years the internal mobile base has had problems. This is a problem for me, because I have to move my machines out of the way when my woodworking classes are in session. I can no longer gently lower the jointer. It slams down. And the other day I had the jointer in the raised up position, and it randomly slammed down when I was across the room. This may just require some troubleshooting with a Grizzly technician, but it causes my fence to go out of square every time the jointer is lowered.

Grizzly has come out with a new 8-inch jointer that has a few features that really appeal to me: the Grizzly G0495X jointer (see the G0495X here on Amazon):

The Grizzly G0495X jointer has a longer parallelogram bed than mine (83-inches long), rack & pinion fence adjustment (that makes it easier to get the fence to 90 degrees to the bed), and most importantly wheels to precisely adjust the infeed and outfeed tables, rather than the levers that mine has. This jointer comes with a helical style cutterhead, which (as mentioned above) may possibly give a slightly better surface on highly figured woods than a spiral cutterhead. And it has a digital height readout, so you know precisely how much you’re moving the tables. This is my dream jointer in the 8-inch width. Of course, if money were no object, I would get a 12-inch jointer or 16-inch jointer! If $2,700 (with shipping) is a bit too expensive for you, then I’d recommend buying my Grizzly jointer model (Grizzly G0490X), which is about $1,000 less expensive.

If you want to research some other power jointer brands, then here are some places to look:

TOOL GUIDE SHORTCUTS:

HAND TOOL BUYER’S GUIDES

- Intro to Buying Woodworking Hand Tools

- Workbench & Tool Storage

- Layout, Marking, & Measuring Tools

- Handplanes

- Handsaws

- Chisels

- Sharpening & Honing Supplies

- Mallets & Hammers

- Hand Drills, Braces, & Bits

- Tools for Curved Work

- Tools for Green Woodworking

- Woodworking Clamps, Gluing & Fasteners

- Tools for Wood Carving

- Products for Wood Finishing, Sanding & Scraping

- Wood Turning Tools & Lathes