How to Make a Mortise and Tenon Joint with Woodworking Hand Tools

7 Simple Step Mortise and Tenon Joint Lesson will Teach You How to Improve Cutting Tenons and Chopping Mortises with Woodworking Hand Tools.

![]() By Joshua Farnsworth | Updated Mar 01, 2022

By Joshua Farnsworth | Updated Mar 01, 2022

How to Make a Mortise and Tenon Joint with Woodworking Hand Tools

7 Simple Step Mortise and Tenon Joint Lesson will Teach You How to Improve Cutting Tenons and Chopping Mortises with Woodworking Hand Tools.

![]() By Joshua Farnsworth | Updated Mar 01, 2022

By Joshua Farnsworth | Updated Mar 01, 2022

Disclosure: WoodAndShop.com is supported by its audience. When you purchase through certain links on our site, we may earn a small affiliate commission, at no cost to you. Learn more.

Introduction

This video and article will simplify the process of cutting mortise and tenon joints with only a few traditional woodworking hand tools. With a little practice, you should be able to make a nice mortise and tenon joint in under 10 minutes! The video is a quick tutorial, but the article and photos below go into great detail about how to make a mortise and tenon joint by hand.

But before jumping into the 7 steps, I first want to (a) clarify the parts of a mortise and tenon joint, (b) explain what mortise and tenon joints are used for in furniture making, and (c) tell you which hand tools you’ll need for making a mortise and tenon joint:

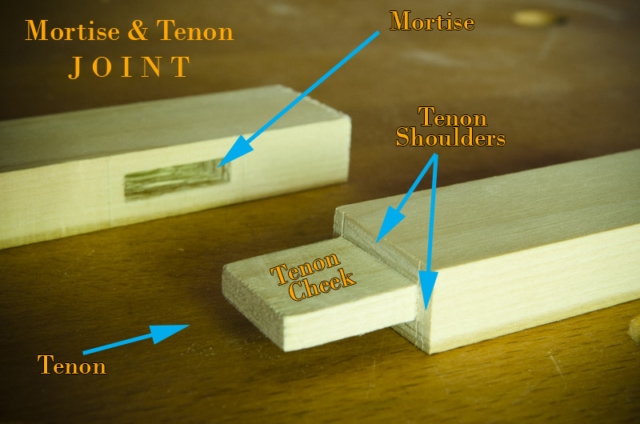

A. Anatomy of a Mortise and Tenon Joint

Throughout this lesson I’ll be referring to different parts of the mortise and tenon joint. So in the above diagram you can see the anatomy of a mortise and tenon joint so you don’t get confused. As you can see, the tenon fits into the mortise. The part of the tenon that fits into the mortise is called the tenon cheeks. The tenon shoulders ride above the mortise on the mating board.

B. What is a Mortise and Tenon Joint Used For?

The mortise and tenon joint (also called “mortice and tenon joint” in British countries) is one of the strongest and most-widely used woodworking joints. It is an effective joint for holding together tables, chairs, doors, cabinets, windows, tool chests, clocks, timber frame buildings, and many other pieces of wooden furniture.

Because of it’s strength and many uses, the mortise and tenon joint is one of the very first woodworking joints that beginning woodworkers should learn. Even power tool woodworkers should learn the fundamentals of how to make a mortise and tenon joint with traditional hand tools, because it will help them better understand cutting tenons and chopping mortises.

C. Woodworking Hand Tools Required for Making a Mortise and Tenon Joint

You don’t need a lot of woodworking hand tools to make a traditional mortise and tenon joint. Here are the tools that I used:

- Brass wheel marking gauge (update: my new favorite)

- 6-Inch Combination Square

- Dovetail Saw

- Carcass Back Saw

- Joiner’s Mallet

- Pig Sticker Mortise Chisel

- Marking Knife

- Woodworking Clamps

- Wood Chisels

- Woodworking Workbench

- Fine tip pencil

To make things easier for beginners I would recommend that you simply purchase an inexpensive pre-dimensioned stick of wood (e.g. poplar) for practicing. Make sure it’s square and straight and flat. Make several mortise and tenon joints, one after another, to really learn this method.

If you can only afford a single marking gauge (two middle gauges), that’s just fine. But you can speed things up with a dual marking gauge (below far right) or mortise gauge (below, far left):

Step 1: Mark the Tenon Shoulder Line

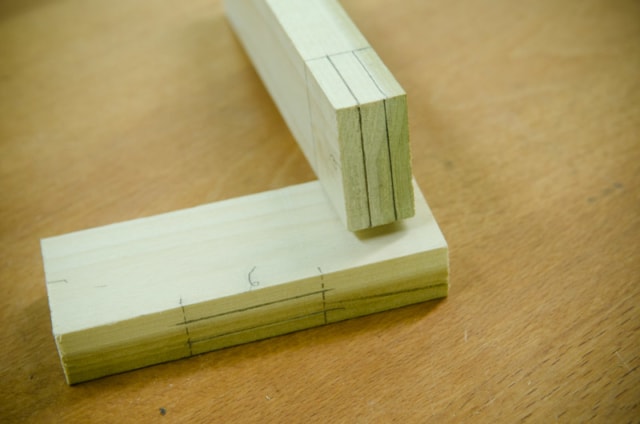

The first step to make a mortise and tenon joint is to lay your boards out on your workbench and butt the tenon board up against the mortise board, so you can see exactly where you want them to join. Make some reference marks on the face and edge of each board so you remember which faces and edges you should mark from in later steps. These will be referred to as your “reference faces” and “reference edges”:

Next you will mark the shoulder line. As mentioned in the anatomy section, the shoulder is where the tenon will stop against the mortise. Think of putting your head in a very small hole in the ground. Your head will go in, but your shoulders will stop at the top of the hole. Lay the tenon on top of the mortise and decide how deep you want it to go into the mortise.

If you’re making a common hidden tenon (like I’m making in this lesson), position your board so it stays back from of the end of the back of the mortise (see above). I’d say this is around 1/4th of the way back from the edge. And make a tick mark on the tenon board with your pencil.

What if you’re making a “through-tenon”? You might be asking yourself: What in the world is a through tenon?

A through-tenon is a tenon that goes all the way through the mortise (see above). If you’re doing a through-tenon, then layout your board so that the tenon hangs out the other side a bit, and make a tick mark, as shown here:

Now set your marking knife on that pencil mark, and use a combination square to mark the line all the way around the tenon board:

Make sure to always have part of your combination square touching the reference face or reference edge that you marked with your pencil line. If your board is perfectly square, then the knife lines will meet up whether you mark from the reference face and edge or not. But using a reference face and edge will ensure your joint will fit together if you only have one square face and edge.

Step 2: Mark the Tenon Cheeks and the Mortise Walls

The next step is to mark the tenon and the mortise boards with a marking gauge or a mortise gauge. A mortise gauge will hold two measurements at once (this style of metal mortise gauge is also called a “dual marking gauge”):

Not every board has the same thickness, so as mentioned above, do all your marking from the same reference face to ensure the tenon will fit into the mortise. I like to mark my faces with some sort of squiggly mark:

As shown below, set your mortise chisel on the top edge of your tenon board (centering it by eye) and set your mortise gauge’s inner cutter to touch the edge of your mortise chisel:

If you don’t have a mortise gauge (or dual marking gauge) you can use a normal marking gauge:

Now that your inner marking gauge cutter setting is locked in, scribe the inner cutter around the end of the tenon, from shoulder line to shoulder line:

Don’t change your gauge setting yet. Run that same inner cutter on your mortise board:

Now go ahead and set the outer cutter to line up with the outer edge of the mortise chisel:

And this is what it will look like if you’re using a normal marking gauge with a single cutter:

Then, just like before, scribe the outer tenon line, all around the top of the tenon, from shoulder line to shoulder line:

And here is what it would look like using a single marking gauge:

Keeping the same setting on your marking gauge, scribe the outer line on the mortise board:

And here’s the view with a marking gauge:

The mortise should now look like this:

And the mortise should look like this:

Here’s a different view:

Note: if you’re making a “through-mortise” (like below) then mark both edges of the mortise.

If you have multiple mortise & tenon joints to build, then you now probably realize how much time will be saved by having a mortise gauge rather than just a single marking gauge. You won’t have to re-create the measurements over and over again. You’ll simply keep both measurements locked into your gauge.

Step 3: Saw the Tenon Cheeks

Now you will use a back saw to cut the tenon “cheeks”, or the faces of the tenon. You should use a backsaw with rip teeth because you’ll be cutting down with the grain. If you’re cutting a small tenon, like this, then a small dovetail saw will work fine:

But if you want to cut a larger tenon, then a rip tenon saw should be used:

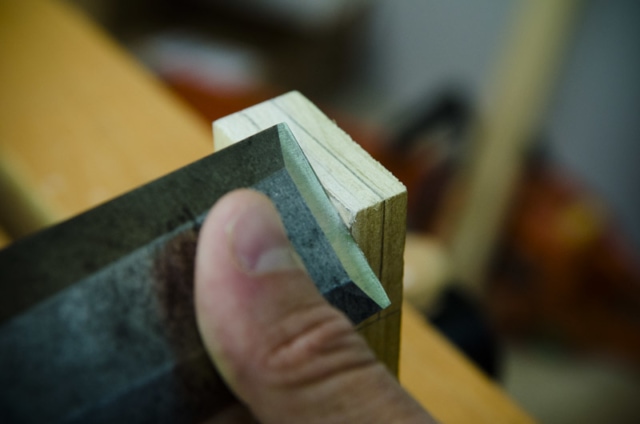

Use a bench chisel to cut out a little notch to provide your saw with a track for starting into the cut. It really helps with stability and straight cutting:

Your saw will rest against the notch wall:

Start the cut at a 45 degree angle, then start sawing horizontal, across the top end grain, staying a hair to the waste side of your line.

Once you’ve made a very shallow kerf on top of the board, move back to a 45 degree angle and continue sawing down to the baseline/shoulder line:

Flip your tenon piece around in the vice and saw from the other side, but in your new kerf that you just created on top of the board. The kerf that you already created will guide your saw downward in an accurate fashion. You can saw horizontally this time. Just make sure you stop before you reach the baseline/shoulder line:

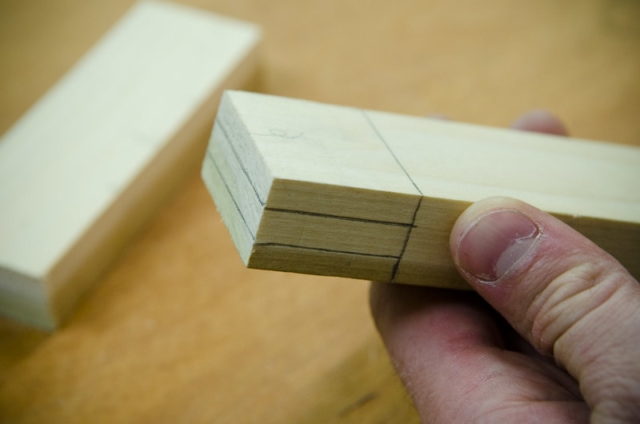

Repeat the same steps on the other line that you marked on the tenon, then you’ll have two saw cuts / kerfs running down the tenon:

Whew! Sorry if that was confusing, but the above video should clarify any mystification. The rest is pretty simple now…

Step 4: Remove the Tenon Cheeks and Cut the Shoulders

Now we move on to removing the tenon cheeks and shoulders from the tenon. Since some of these cuts are across the grain, ideally you should use a different backsaw with crosscut teeth: a carcass backsaw:

If you can’t afford another back saw yet, you can indeed use your dovetail saw (with rip teeth). The teeth are small enough so you won’t notice a huge difference. It’ll be a bit harder, and won’t cut quite as cleanly.

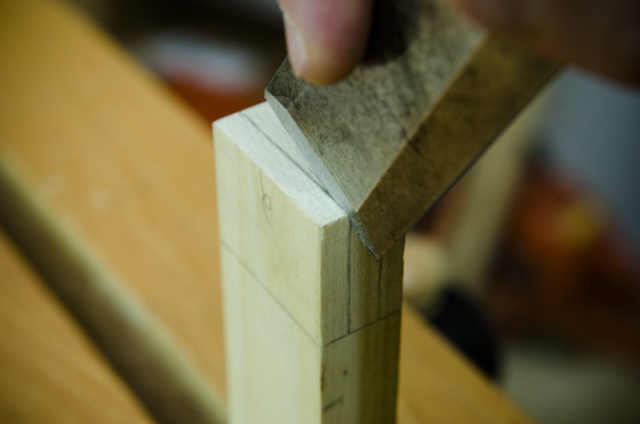

Now secure your tenon piece against a bench hook (or with a hold fast or in your vice some how), and deepen your shoulder line with a wide bench chisel and wooden mallet. Place the chisel precisely in your shoulder line (you previously created it with a marking gauge…remember?) One or two medium strokes with the mallet is deep enough. Make sure your chisel’s bevel is facing the tenon, like this:

Now use your wide bench chisel to create a little angled trench to guide your crosscut carcass saw:

This will allow your backsaw to rest against the shoulder, and will provide a more accurate guide when sawing downward. Now place your cross cut carcass saw in that trench and saw straight down:

Be extra careful to not saw too deep. Slowly “creep” up to the line. If you cut your long rip cuts deep enough, then the waste piece should simply pop off the cheek like this:

But often you need to go back into your long rip cuts and “creep” down a bit with a dovetail saw:

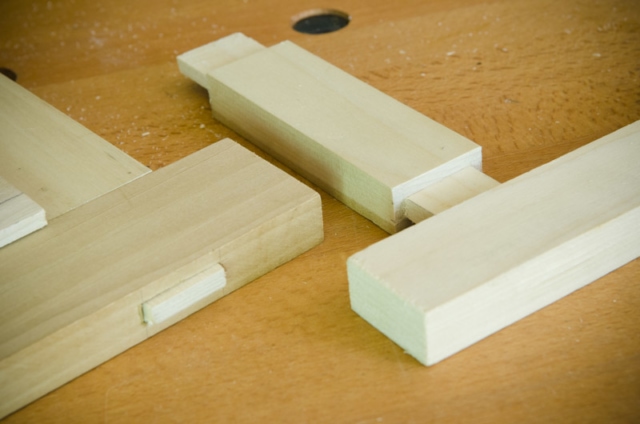

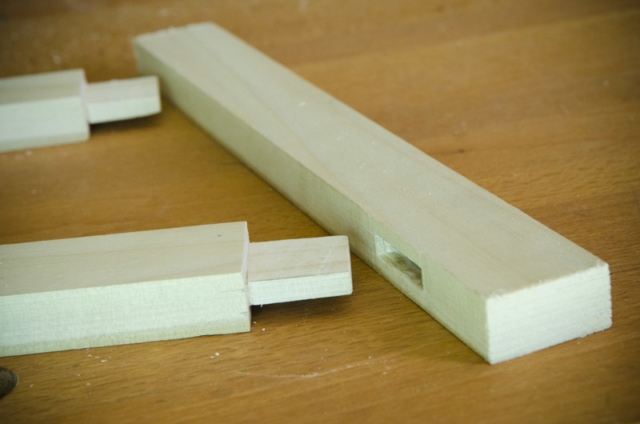

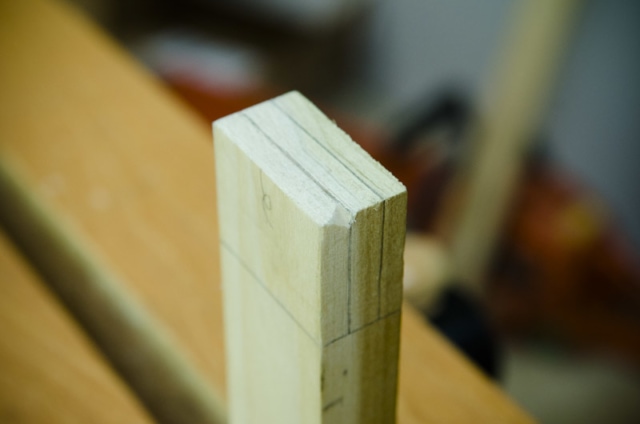

Repeat this same step on the other side of the tenon. Now your tenon should look like this:

If your sawing wasn’t perfect (don’t be embarrassed) you can straighten up your tenon “cheeks” and “shoulders” with your bench chisel (and a shoulder plane, if you like). But be careful to NOT place your hand in the direction of the chisel’s travel, like this:

Step 5: Cut the Tenon Sides

Use your square to draw vertical lines down both sides of your tenon and cut off a tad from each side with your dovetail saw:

And this is what the tenon looks like with one side removed:

Use a cross cut carcass back saw to cut the side shoulders pieces off:

These measurements aren’t critical because you will scribe the mortise width from whatever size you just trimmed your tenon to…so it’ll fit tight.

Step 6: Layout the Mortise

Your tenon is finished and ready for creating the mortise. The tenon should now look like this:

Lay your freshly finished tenon on your mortise and use a pencil or marking knife to make a tick marks on the mortise where the tenon sits. Use your square and marking knife to scribe a line from the tick mark so that you have the full outline of your mortise:

Above you’ll notice that the crossed out area is where you will chop the mortise with a mortising chisel.

Step 7: Chop the Mortise & Fit the Joint

Now it’s time to use your mortise chisel (or “mortice chisel” for my British friends) for chopping your mortise. I’ve seen several methods for chopping a mortise, but I’ll sharing my favorite method. I like to setup my mortise chopping using a traditional method from England:

The mortise board is held stable between the clamp and a board (that I placed in a vice). The mortise board also sits on top of another board. Again, the squigly lines are where you’ll be chopping with your mortise chisel:

The width of your mortise lines should perfectly match your mortise chisel’s width. The sides of the mortise chisel will be barely touching your layout lines:

STOP! You do not want the chisel to initially chop on the end lines or else the force and expansion will lengthen your mortise opening, which would prevent a perfect fit for your tenon. So start chopping with your mortise chisel about 1/4″ inch away from each end of your mortise lines (see above). By “chop” I mean use your wooden mallet to hit the top of the mortise chisel. Chop straight downward. The angle of your mortise chisel’s bevel will cause the mortise chisel to go downward at an angle.

Keep chopping until you feel a lot of resistance, then pull the chisel straight out of the hole and “walk the chisel” down the edge of the board a little bit and chop downward again. Repeat this until you get within 1/4″ of the other end of your mortise and stop. I said stop! Just like the beginning, don’t chop on this line either…at least not yet. Flip the chisel around and repeat the chopping process going the other way, trying to start the chisel’s bevel on an unchopped spot. Your hole will get deeper and deeper.

Warnings: I try not to wiggle the chisel sideways when pulling it out of the mortise because I don’t want to alter the width of the hole. I also try not to use my mortise chisel to pry loose chips/chunks out of the mortise. Just keep chopping through those chips. If they really be come cumbersome, use an awl to remove the chips, but don’t ruin your mortise edges when prying. When you’ve marched back & forth down the mortise a couple times (and relieved the pressure) you can go ahead and place the mortise chisel just shy of each line and drive straight down to create a clean mortise wall.

How do you know when to stop chopping? I use my combination square and adjust it’s length to match my tenon’s length:

Presto! You now have a perfect depth gauge…just stick it in the mortise to see how close you are to your final mortise depth:

When your combination square bottoms out, then it’s time to stop chopping.

Note: If you are chopping a through-tenon you would just repeat this marking & chopping process on the other side, and meet in the middle. You shouldn’t try to exit through one side…it’ll give a nasty exit wound. Alright, back to normal mortises:

Now grab your 1/4″ bench chisel (or smaller) and pare/trim the inside edges of the mortise until they look vertical.

But don’t pare too much or the joint may become too loose.

Try dry fitting your tenon first to see how tight it is. Don’t force the tenon into the mortise with a heavy mallet blow, or the mortise could split. I prefer using just my hands:

If your joint feels too tight, but your mortise walls look nice and vertical, then don’t pare the mortise anymore. Turn your attention to trimming the tenon instead. You can trim it using a shoulder plane or a wood chisel. Just take small cuts then retest the fit.

But don’t let all this trimming & paring scare you. If you followed this tutorial, then you shouldn’t have to do much trimming, if any at all. Hand pressure, or a few light taps with a mallet should seat the tenon in tightly.

The more mortise and tenon joints you make the faster you’ll get at it!

Conclusion

Congratulations! You can now cut the most important joint in traditional woodworking! Now choose a project that has a good number of mortise & tenon joints so you can reinforce what you just learned. Please comment below if you have questions or tips on making a mortise and tenon joint.

I have long admired the strength of the mortise & tenon joint in many pieces of fine furniture. Until I watched Joshua’s instructions never considered tackling this joint myself.

I an a new woodworker and I look forward to learning from Wood and Shop. Thanks Joshua for sharing instructional videos for others who want to learn.

Very nice explanation with a lot of visual resources. Thank you for sharing.

You’re welcome Alberto! Where are you writing from?

I love how thorough these tutorials are. I currently am teaching woodshop to a group of high schoolers and going through all the classic methods by hand are not without there own difficulties. I think using these articles as reference will allow my students to read and review the techniques I am demonstrating in class. Thanks for posting!

You teach woodshop in high school? Awesome! I’m so grateful to my high school woodshop teacher (Mr. Cherry). I’d be grateful to hear back how my tutorials help them out…and posting some photos on the forum of your class would be fantastic also.

Thank you Joshua for the very detailed instruction on mortise & tenon joints. I’m new to woodworking and want to learn this very strong method of joinery.

Glad I could be of help Archie!

Wonderful tutorial. My sons and I have started woodworking recently and we are really enjoying the time together. The nice thing about traditional woodworking with hand tools is that we can spend an afternoon woodworking and still be able to carry on a conversation. Thank you for your very clear explanations of this traditional joint!

You’re welcome Steve! Family is the most important thing in our lives, so it makes me happy to hear that you’re learning woodworking together. How old is your son?

Do you use glue when finishing the assembly of any item with mortise and tenon? Except of an item is designed to break down, of course,

that would be self-defeating, no?

Hi Christopher. I do use some glue in mortise and tenon joints, especially for furniture that is meant to stay together. But you can also use draw boring to tighten the mortise and tenon joint, in case you ever want to take it apart: https://woodandshop.com/how-to-drawbore-mortise-and-tenon-joints-part-10-of-build-a-dovetail-desk-with-hand-tools/

amazing, i think i can make this if i can find the correct hand tools. I want to make a door, half glass and half solid for the cabin on my boat

You can totally do it Gary! What type of boat?

looks like my response went to email

the boat is a fiberglass cut down with a wooden wheelhouse. She is 27 ft long and I use her to harvest blue crabs on the Chesapeake. I have had a hard time finding the correct tools. Since this will more then likely be my only project of this nature I do not want to spend an arm, leg and first born.

Nice Gary! I had a 25 foot sailboat that I sailed on the Rappahannock and Potomac Rivers that past couple years. Now I’m down to a 15′ rehabbed sailboat and a Sunfish. Gotta love catching & cooking the blue crabs!