How to Choose Hand Saws for Wood Working

Which Hand Saw for wood working do you need for getting started? Joshua talks about the Best Woodworking Hand Saw, Back Saw, Dovetail saw, Tenon Saw, and more (Part 2/3)

![]() By Joshua Farnsworth | Updated Mar 01, 2022

By Joshua Farnsworth | Updated Mar 01, 2022

How to Choose Hand Saws for Wood Working

Which Hand Saw for wood working do you need for getting started? Joshua talks about the Best Woodworking Hand Saw, Back Saw, Dovetail saw, Tenon Saw, and more (Part 2/3)

![]() By Joshua Farnsworth | Updated Mar 01, 2022

By Joshua Farnsworth | Updated Mar 01, 2022

Disclosure: WoodAndShop.com is supported by its audience. When you purchase through certain links on our site, we may earn a small affiliate commission, at no cost to you. Learn more.

Buy a Cross Cut Back Saw: Carcass Saw

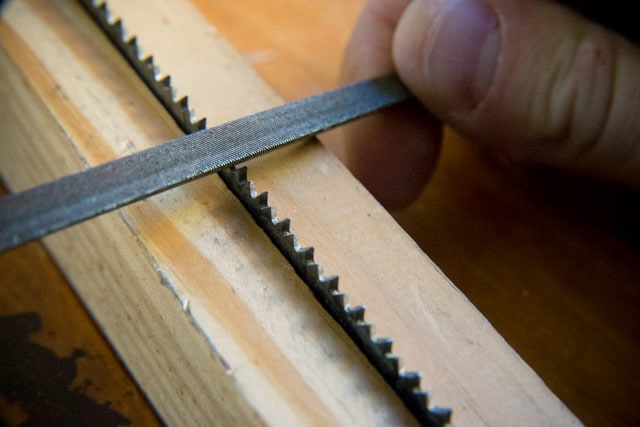

Now I’ll move on to talk about another very useful hand saw for wood working: a carcass crosscut saw. A carcass saw is a longer back saw with crosscut teeth used for cutting cleanly across the grain. It is used primarily for cutting precision wood joints. If you can only afford one back saw right now, then you can just stick with a dovetail saw with rip teeth for a while, because the teeth are so small that it can still make fairly good cross cuts. But if you want a cleaner cut, and the ability to make longer cuts (like a shelf dado) then a longer crosscut saw, like a “Carcass” saw, is what you should buy.

Traditionally, the frames of furniture casework were called a “carcass”, so the common crosscut back saw used to cut dado joints and mortise & tenon joints was called a “carcass saw”. Typically a Carcass back saw is longer than a dovetail saw, so that it can be used to cut longer dado joints for shelves.

Vintage carcass saws for sale are rarely listed as “a carcass saw”. A lot of uninformed sellers list them as a “dovetail saw” or a “tenon saw”. But at around 11″ to 14″ long, with a saw plate less tall than a tenon saw, they’re obviously not dovetail saws or tenon saws. So keep that in mind when searching around for a crosscut hand saw for wood working. Carcass back saws will have around 11-14 ppi. A tenon saw can easily be converted into a carcass saw by sharpening the teeth for cross cutting.

Read the above section on buying a dovetail saw to see why I chose to invest in new Lie-Nielsen back saws. So years ago, after a lot of research, I decided to also purchase their 14 ppi cross cut back saw (see it here) for cutting joinery across the wood grain (e.g. cutting tenon cheeks).

This is the carcass saw of choice among students in my woodworking school, because of the thin saw plate and ease of cutting. These carcass saws come ready to use from Lie-Nielsen, and won’t need to be sharpened for a long time.

I also own several Disston back saws that I have changed to crosscut back saws, like this on ebay Disston No. 4 steel back saw:

It really is a great back saw, but required a bit of refurbish work and sharpening to get it cutting nicely. But I like refurbishing hand tools and sharpening hand saws, so it was not a chore for me.

If you decide that you’d prefer to buy a vintage/antique back saw, make sure to inspect the blade for kinks. Hold it up to your eyes, and sight down the tooth line to make sure the saw plate is straight.

If you’ve inherited (or accidently purchased) a hand saw with a kinked saw plate, as a last resort you can smack the back of the steel/brass back of the saw on a piece of wood and it may straighten out, but not always (and it can make it worse), so it’s best to buy back saws with straight saw plates. Also check the handles for broken pieces. A broken saw horn is very common, but certainly not a problem if you’re looking for a low priced back saw.

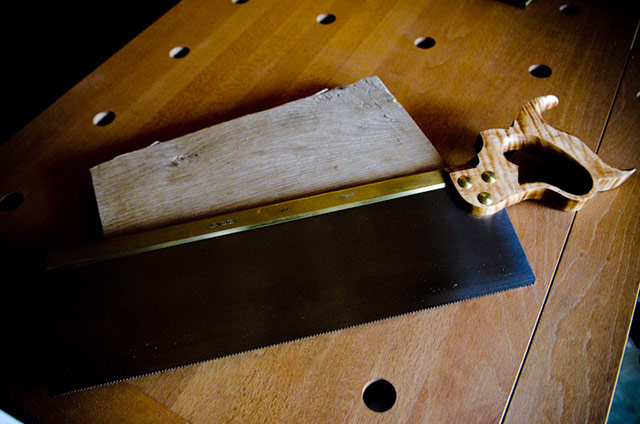

Buy a Rip Back Saw: Tenon Saw

Now I’ll move on to talking about choosing the best tenon saw for woodworking. A large tenon saw (with rip teeth) may not be required at first, because a lot of tenons that you may cut are small enough to just use a dovetail saw. But if you plan on cutting any tenons longer than the height of your dovetail saw’s plate, then you’ll need a tenon saw.

Next to miter saws, tenon saws are the largest back saws. And they’re used for ripping along the grain, predominantly on tenon cheeks. On Ebay and in flea markets you’ll see people trying to pass carcass saws off as tenon saws, which is incorrect. Tenon saws are much larger (around 22-ish inches long with a 16-ish inch long blade x 3 or 4 inches tall) with 10-14 ppi. But don’t get too caught up on the seller’s name of the saw. Just get a back saw size and tooth configuration that fits the job you require, or modify it to do so.

Years ago, after talking to some friends I decided to purchase Lie-Nielsen’s Tenon Rip Saw (16″ long blade version) for around $150. You can find it here. I chose the “thin plate” version ( .020″ thick) for easier sawing. It was really nice having such a great saw arrive so sharp.

Over the years, however, I have found this tenon saw to be too big. I just don’t need a 4 inch tall saw plate.

If you want to refurbish and sharpen an antique tenon saw, then check with some tool dealers or on Ebay. Just make sure the saw plate is around 3-inches tall.

Buy a Miter Box Back Saw with a Miter Box

What is a miter box? A miter box is a frame that holds a long back saw to make accurate cuts at different angles. I use my antique miter boxes and miter back saws all the time because I can set the angle and make very precise cuts across the grain. And I can repeat the same length cut over and over again for multiple pieces. In my opinion, the accuracy and cleanliness is even better than with the power miter saw (a.k.a. “chop saw”). Using a miter box saw saves you from having to spend a lot of time truing up the edges of a board with block planes or chisels. It can give you perfect 90 degree angles.

Most of the antique Disston, Stanley, or Millers Falls miter saws will work just fine, if sharpened properly (if possible, purchase miter box saws manufactured before World War 2). But most antique miter boxes will be paired with a saw, so just find a decent miter box and the saw will likely be good enough. You can fit most any miter back saw with a miter box.

There are different types of miter boxes to consider. I would avoid the type of miter box that uses your carcass back saw (like the Stanley No. 150. See it on Ebay). When I tried one, it injured the blade of my back saw because it clamps down on your hand saw’s back and saw plate. If you stick with the antique Millers Falls miter boxes (see on Ebay) or Stanley miter boxes (see on Ebay), you should be happy.

I own about seven miter boxes and miter box saws, including a Millers Falls 75 miter box (see on Ebay) , a Millers Falls 74 C (see on Ebay), among others. I’ve also used a Stanley 2358 miter box (see on Ebay) and found it satisfactory. I haven’t spent much time tuning any of mine up (aside from sharpening the saw) and they work fine. Just check the parts to make sure they function properly and that no major parts are missing. Almost all of my miter boxes are missing parts, so don’t stress if the one you find doesn’t have all the parts. You can usually find old user manuals (along with parts diagrams) that have been scanned to PDFs for viewing online. Use these to track down your missing parts on Ebay.

Here are some things to look at: Make sure you can lock the box at any angle and check to see if any screws are missing from the guide posts (arms that bob up and down).

If you can’t afford a miter box saw right now, then that’s alright. You can use a crosscut carcass back saw to make your cross cuts (using a bench hook), and true up the end with a shooting board or block plane & try square. It’s just more work.

But if you plan on buying a miter box saw, then try to find your miter box saw locally, like on free classified websites, like Craigslist so you can physically inspect it. I’ve paid $15-$25 for local miter boxes and miter saws. A tool show (like at a M-WTCA meeting / sale near you) is another excellent source, where I have found several of my miter boxes.

Having Miter Boxes & Miter Saws shipped to you is definitely an option but the shipping can raise the price substantially. But if this is your only option for a good saw, most miter boxes and miter box back saws on Ebay have good descriptions and photos. If you can’t find any locally, then check some of these miter box saws out: