How to Choose the Best Table Saw

A Woodworker’s guide to understanding which table saws are the best, and which table saw features & accessories to consider

![]() By Joshua Farnsworth | Updated Feb 28, 2022

By Joshua Farnsworth | Updated Feb 28, 2022

How to Choose the Best Table Saw

A Woodworker’s guide to understanding which table saws are the best, and which table saw features & accessories to consider

![]() By Joshua Farnsworth | Updated Feb 28, 2022

By Joshua Farnsworth | Updated Feb 28, 2022

By Joshua Farnsworth

In this article I’ll help you choose the best table saw for the money, whether you’re a beginner or an experienced woodworker.

How to Choose the Best Table Saw for Beginners

What is a table saw used for? Here’s the process:

After taking a board through the power jointer (to flatten & square up a face and edge) and thickness planer (to obtain a uniform thickness), the last machine that I use to square up my boards is a table saw. First I run the board lengthwise between the fence and saw blade to “rip” the board to the desired width. The jointed edge rides along the fence. Thus, the rip cut gives a uniform width to the whole board. Then I can make crosscuts on the table saw using a miter gauge or shop-made crosscut sled to cut the board to it’s final length.

6 Features to consider when buying the best table saw for beginners

Buying a table saw for woodworking can be a confusing process, because there are so many different table saws with so many different features. I’m writing this article to simplify the process of buying the best table saw for your budget. These are the six factors that I feel are important to consider when buying a table saw, which I’ll discuss in this article:

1. Type of Table Saw: Portable Table Saw vs. Cabinet Table saw

2. Table Saw Power

3. Table Saw Safety

4. Table size (Rip Capacity and Crosscut Capacity)

5. Quality of Rip Fence

6. Buy a New or Used Table Saw?

1. Type: Jobsite Table Saw vs. Contractor Table Saw vs. Cabinet Table saw

The first question to ask yourself when buying the best table saw for you, is “what will I be using the table saw for“? Here are some different types of table saws:

Jobsite Table Saw:

A jobsite table saw (pictured above, left) is a portable table saw that is designed to be carted around a jobsite. This type of portable table saw has the least powerful motor among table saws, but it’s portability may make this table saw right for you. If you’re a wood flooring installer, for example, and the thickest hardwood lumber you’ll be ripping is under 1-inch thick, then this may be the perfect type of saw for you. Some jobsite table saws come with a wheeled base, some come with a base that has folding legs, and some do not come with a stand at all. A base with wheels or folding legs is a nice feature, but does add to the cost of the jobsite table saw.

* Skip to the Best Jobsite Table Saws >>>

Contractor Table Saw:

A contractor table saw (pictured above, right) is a step up from a jobsite table saw in power, but a step down in portability. While a contractor table saw is still considered to be a portable table saw, it is heavier and is a bit harder to move around a jobsite. You can usually tell a contractor table saw by the removable legs that are bolted to the table saw. Due to its heavier weight, it is a table saw that I would personally get help from another person to move. Carpenters and hobbyist woodworkers who need to cut lumber that’s thicker than wood flooring or molding may opt for a contractor table saw.

* Skip to the Best Contractor Table Saws >>>

Cabinet Table Saw:

A cabinet table saw (pictured above, center) is a better choice for furniture makers and cabinet makers who need more powerful motors to cut thicker hardwoods, like for making oak table legs. A cabinet table saw is also perfect for a woodworker who has a workshop where they can keep their large cabinet table saw. They come in varying horse power options, which I’ll talk about in the section below, but they all are considered non-portable because of their large cast iron table top and larger parts. Cabinet table saws have an enclosed cabinet rather than legs. By saying that, it doesn’t mean that a cabinet table saw can’t be moved around your workshop on a mobile base, but it means that the only time it will likely leave your workshop is when you sell your workshop or when you sell the table saw.

* Skip to the Best Cabinet Table Saws >>>

Now that you’ve answered the question “what will I be using the table saw for?“, we can continue narrowing down your best table saw, based on the table saw features that will be best for you.

2. Table Saw Motor Power

As I touched on in the prior section, the power of the motor is a very important consideration because you need your table saw to be powerful enough to cut easily through the wood that you’ll be using. When buying a table saw, the term “horse power” is often used to express how powerful the motor is.

Although it’s not a perfectly accurate measure of the motor’s power, “horse power” (abbreviated “HP”) is a quick way to compare the power capabilities between table saw models. Well, at least the more powerful table saws. Amperage (or “amps”) may be a better way to compare power between table saws once you’ve narrowed down the best table saw options for you. It’s just a little harder to find that number. I’ll discuss Amps in a minute.

Cabinet Table Saw Motor Horsepower

For professional cabinet table saws, horse power ratings range from 1.75 HP to 7.5 HP. As a general rule of thumb, if you want to cut hardwood over 2-inches thick without your motor bogging down, then you should buy a cabinet table saw with a motor over 2 HP. I’ve found that my 3 HP cabinet table saw (see it here) is a perfect balance between performance and budget.

My table saw has never bogged down when cutting thick hardwood for furniture making. So it’s my personal opinion that a table saw over 3 HP is overkill for most furniture makers. However, I don’t usually work with super hard and thick tropical lumber, so a 5 HP cabinet table saw may be a good option for professional woodworking shops that cut a lot of thick tropical hardwood boards. It’s also important to note that table saws with powerful 3 HP motors or larger will draw more amps (again, I’ll clarify this in a minute), and will therefore require you to have an electrician install a 220 volt circuit and outlet in your workshop, if there’s not already one there. (note that 220V / 230V / 240V are the same circuit and plug. Learn more here).

And 7.5 HP table saws are for industrial use, and draw so much electricity that they require a 3 phase electrical connection, which most residential workshops and homes don’t have. So most woodworkers can probably rule out buying a 7.5 HP cabinet table saw.

In the past I owned a 1.75 HP cabinet table saw (pictured above), and while it worked well under most conditions, it did bog down when cutting hardwood boards over 2-inches thick. If you don’t plan on cutting boards that are abnormally hard and thick, then a 1.75 HP table saw may work well for you. That isn’t to say that a 1.75 HP table saw can’t cut hardwood over 2-inches thick. But the feed rate will need to be slowed down substantially, and you may find that the saw slows down. That can lead to a dangerous situation if you’re scrambling to push your board through a dangerous spinning blade that is struggling to get through the wood. If you decide to buy a cabinet table saw under 3 HP, just be extra careful when using thicker, harder boards. But there’s also something to be said about buying a table saw that you won’t have to “upgrade” in the future.

Contractor Table Saw Motor Horsepower

Contractor table saws can also have descent horsepower. You can find some contractor table saws with motors in the 1.5 HP – 2 HP range (like this nice one made by SawStop). This makes a contractor table saw a good option for a woodworker who needs portability, but still needs enough power to cut most hardwoods efficiently. As I mentioned earlier, a contractor table saw with horsepower in this range can still do a reasonably good job of cutting through hardwood boards 2-inches thick or thinner. And a contractor saw will not require you to have a new 220 volt circuit run, although you may need to install a 20 amp breaker if you don’t have one.

Jobsite Table Saw Motor Power

Jobsite table saw motors usually come with motors of 1.5 HP or lower. In fact, many of the more affordable job site table saw models don’t even specify horse power. They use “amps” to specify their motor’s power. That makes it harder to compare their power with higher end table saws. So this is where finding out the “amps” of a table saw is important.

Most jobsite table saws advertise 15 amp motors. This is roughly equivalent to a 1 HP motor. Why are many jobsite table saws made with 15 amp motors?

Because most household circuits are 15 amps, and the manufacturers likely wanted to make table saws that wouldn’t trip the circuit breaker when someone is working on a jobsite with limited outlet options. If a table saw draws more than 15 amps (like with a table saw with 1.5 HP to 2 HP) then it would trip the 15 Amp breaker, and you would need a circuit breaker with more amps, like a 20 amp breaker.

Table saws with 3 HP motor (or larger) will draw so many amps that you would need a special 220 volt breaker and plug, as mentioned earlier. You just can’t use a table saw that powerful on normal 120 volt household plugs.

So if you want to make an apples-to-apples comparison between table saws, then look up how many amps the different table saws draw. And the amps will also tell you what type of electrical circuit you’ll need for your workshop.

3. Table Saw Safety Features

One of the most important features that you should consider when buying a table saw is safety features. There are more major injuries in woodworking shops on a table saw than on any other machine. I’ve known very experienced woodworkers who have cut their fingers off at the table saw when someone walked into their workshop to say hello. Taking your eye off a table saw blade, even for an instant, can be catastrophic. And I know other woodworkers who switched almost fully to hand tools because of a table saw scare that he had.

But thanks to a few modern innovations in table saw safety, there’s less to fear than there used to be. Most vintage table saws were certainly well-built, and usually last longer than many new table saws. But the old table saws lack the safety features of new table saws. To me that’s a big deal.

I’m not saying that because of the modern safety features you should be care-free when using a table saw, but you at least don’t need to be scared. Just cautious. So what are the most important table saw safety features that should be included with the best table saw?

Blade Guard

Most table saws now come with a plastic blade guard to help with protecting a woodworker’s hand from the dangerous spinning table saw blade. I think this is a great table saw safety feature. Although, it’s not always convenient to keep the plastic guard on during all cuts, so it’s not a fool-proof table saw safety feature.

Riving Knife or Splitter

A riving knife and a splitter are pieces of metal that sit just behind a table saw blade to prevent a dangerous kickback. This works by preventing the newly cut parts of your board from closing up and pinching the blade. A riving knife is attached to the part of the table saw that raises the blade up and down, so the riving knife always stays at the same height as the blade. A splitter is usually attached to a blade guard, and essentially accomplishes the same thing as a riving knife, but it gets removed when the blade guard gets removed for cross-cutting. Make sure that whichever table saw you buy comes with a riving knife or splitter, or at least a spot where you can add one.

Anti-kickback Pawls

Anti-kickback pawls are another safety feature that are connected to a blade guard. They are basically spring-tensioned claws that hold the wood down when the blade wants to throw the wood upward and back at you. This feature is especially important to use when ripping large pieces of wood, like plywood.

Safety Power Switch

Having a large safety power switch is really important so you can quickly kill the power to the table saw in case something goes wrong. A very large paddle is important so you can shut the table saw off with your leg, if needs be.

Flesh-detecting Instant Table Saw Break

The flesh-detecting instant break is without question the most important safety innovation that has ever been invented for table saws. This technology detects contact with human skin and stops a table saw blade within 5 milliseconds, leaving only a small nick, rather than detached fingers. Dr. Steve Gass invented this industry-disrupting technology in 1999, and has saved thousands of fingers around the world with his SawStop table saws. Here’s a great video that shows how the SawStop saw technology works:

Don’t get me wrong. Most table saw manufacturers have made a long stride with safety features. But only one company holds the patented technology to prevent the table saw from cutting your fingers off. The sad thing is that all other table saw manufacturers rejected SawStop’s technology when they were approached about licensing it.

4. Table Size: Rip capacity and Crosscut capacity

This feature correlates perfectly with the type of table saw you buy. Smaller jobsite table saws and contractor table saws will have a smaller table top, which limits the how far you can slide the rip fence from the blade. This means the size of wood you can cut is more limited. Whereas on a larger cabinet table saw, the table top is large, which means the rip fence can slide farther away from the blade. On my SawStop table saw I got an extension table that has a extension rails that the rip fence glides along. This gives me much more ripping area than I would ever need.

Larger table saws also have more table space between you and the blade. This makes it easier to crosscut wider boards.

Smaller table saws are also quite limited in this dimension. And some industrial saws add even more space here to allow for crosscutting really large boards. If you don’t plan on ripping really wide boards or sheet goods, then a smaller table saw may work well for you. But if you want to rip wide boards, then look for a table saw that has a lot of extension away from the blade.

5. Quality of Table Saw Rip Fence

Not all table saw rip fences are created equal. A weak and flimsy rip fence can not only make it frustrating to lock down your desired width, but it can lead to a dangerous situation. Most higher-end cabinet table saws will have a really solid and smooth-gliding fence. But the smaller the table saw, the less substantial the rip fence. If you’re planning to buy a smaller table saw, then go try out the fence. See how smooth it moves from left to right, and how solidly it locks down. Do the same if you’re looking at a used table saw.

But also realize that you can buy good aftermarket table saw rip fences. Here are some table saw rip fences that you can look at:

6. Buy a New Table Saw or a Used Table Saw?

So should you buy a new table saw or a used table saw? Well, it all depends on quality and condition. I guess it goes without saying that you can buy great table saws that are used or new, and you can also buy bad table saws that are used or new. For new table saws, condition isn’t really an issue, since they haven’t been used. So if you want a new table saw, then use my above criteria for choosing based on quality.

For buying a used table saw, you should use my above criteria for choosing a quality table saw, but also inspect the table saw to see what condition it’s in. Just like buying a used car, you can get a lightly used table saw in great condition, and you can get a lemon that has too many miles and too much abuse.

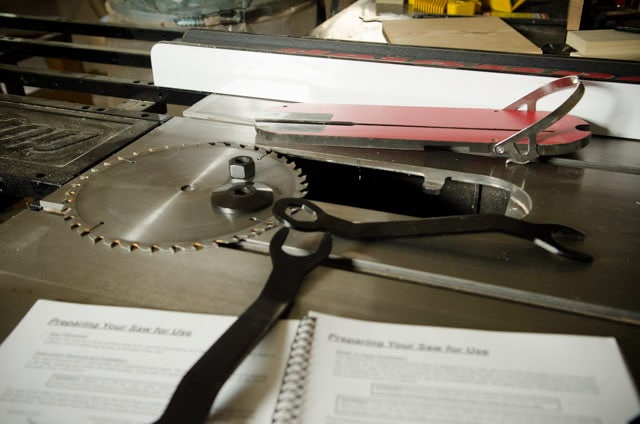

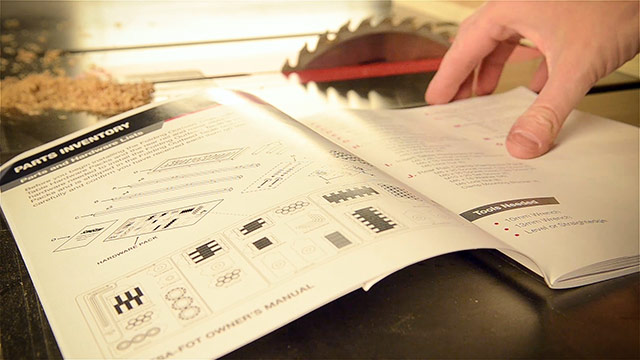

Inspect the used table saw and look carefully for rust, pitting, and any loose parts. Also, just because a used table saw looks new, it doesn’t mean that it doesn’t have problems. Just like buying a used car, take a “test drive” with the used table saw. Or at least watch the seller using it. Run some different types of wood through the blade, both hard and soft. Realize that the blade may not be new, so don’t expect a perfect cut, but it’ll give you an idea if the saw has problems. If the seller won’t let you try out the table saw, or at least watch him/her use it, then walk away, no matter how good the price is.

Now let’s talk about buying a new table saw. If you’re buying a new table saw, then you may not feel like you’re getting a super great “deal”. But remember that you won’t be spending time repairing the table saw, and a manufacturer’s warranty will give you some peace of mind.

Setup time is another minor issue to consider. You need to weigh the options of spending time setting up a new table saw verses the time required for any rehab work that may be needed for a used table saw. If a used table saw is in good condition, then you can get cutting on day one. But if it needs rehab work, then your woodworking projects may need to be postponed until you’ve fixed the table saw up.

But on the other hand, I’ve spent many hours setting up new woodworking machines. Some companies are better than others at making setup easy and quick. I would have to say that for new woodworking machinery, SawStop and Felder gave me the easiest setup experience, and Grizzly the worst.

Some companies are just lazy when writing their user manuals, and they also want you to do a lot of setup work that could have been done in the factory.

Aside from inspecting and trying out a new or used table saw, do some research on the best table saw brands and models before you make a purchase. In the next section I’ll share some of the best table saw models (cabinet table saws, contractor table saws, and jobsite table saws), and I’ll also share some of the table saw brands that have dropped in quality in recent years. Knowing details like this will save you a lot of time and money.

But if you don’t mind taking the safety rick, and you like rehabbing old, solid woodworking machinery, then a used or vintage table saw may work great for you. But if you don’t want to spend the time rehabbing an old table saw, and you would prefer more modern features, especially safety features, then go ahead and buy a new table saw, or a used table saw that has more modern features.

Which is the Best Table Saw?

As mentioned above, table saws come in a few different categories: cabinet table saw, contractor table saw, and portable table saw / jobsite table saw. Below I’ll briefly discuss the best table saw models in each category:

Best Cabinet Table Saw

SawStop 3HP Professional Cabinet Table Saw

SawStop holds a patented technology for stopping a saw blade in 1/1000 of a second when it senses human flesh. The saw blade is forced down into a brake, leaving only a minor scratch on your finger, rather than cutting your fingers off. Yes, the saw blade and the SawStop brake have to be replaced, but that cost is minuscule compared with a trip to the Emergency Department and a lifetime without fingers. And the same comparison can be made when trying to save a thousand dollars by buying a cheaper table saw. The risk isn’t worth the savings.

But please remember that even though a SawStop saw will stop you from cutting your finger off, it can still cause kickback of wood, like with other table saws. So you still need to use safety practices.

SawStop table saws come in a few different sizes, from a jobsite contractor saw all the way up to an industrial table saw. This is the model of SawStop cabinet tablesaw that I purchased, which is available with free shipping on Amazon. I find that the 3 horsepower cabinet saw has enough power to cut through thicker hardwood boards than a lower horse power table saw. I’ve owned a 1.75 HP table saw, and it worked in most situations, but bogged down on thicker wood. And after talking with a friend who owns the Industrial SawStop saw (comes in 3HP and 5HP) I felt that the industrial SawStop saw wasn’t worth the extra cost for me, as my 3HP cabinet table saw can handle anything that I can use on it.

So a 3HP table saw is ideal for most woodworkers. However, my friend loves the larger table size of the Industrial SawStop. In order of most expensive to least expensive, here are the different models and feature combinations for you to check prices on (the links lead to the product pages on Amazon):

- SawStop PCS31230-TGP252 3-HP Professional Cabinet Saw Assembly with 52-Inch Professional T-Glide Fence System, Rails and Extension Table (this is the model and package that I own)

- SawStop ICS5123052 5Hp Industrial Cabinet Saw 52″ Ind Fence System

- SawStop ICS31230-52 3Hp Industrial Cabinet Saw 52″ Ind Fence System

- SawStop PCS31230-PFA30 3-HP Professional Cabinet Saw Assembly with 30-Inch Premium Fence System, Rails and Extension Table

- SawStop PCS175-TGP236 1.75-HP Professional Cabinet Saw Assembly with 36-Inch Professional T-Glide Fence System, Rails and Extension Table

- SawStop PCS175-PFA30 1.75-HP Professional Cabinet Saw Assembly with 30-Inch Premium Fence System, Rails and Extension Table

- SawStop CNS175-TGP36 1.75Hp Contractor Saw 36″ Prof T-Glide Fence System

- SawStop CNS175-SFA30 1.75Hp Contractor Saw 30″ Aluminum Fence System

- SawStop JSS-120A60 1.5HP Jobsite Saw PRO with Mobile Cart Assembly

You can also compare prices for SawStop table saws at these stores:

- Shop SawStop cabinet table saws at WoodCraft

- Shop SawStop cabinet table saws at Rockler

- Shop SawStop cabinet table saws at Highland Woodworking

And you can see other table saw models at these stores:

- See all table saws at WoodCraft

- See SawStop table saws at WoodCraft

- See all table saws at Rockler Woodworking

- See SawStop table saws at Rockler Woodworking

I really like having the model that comes with the larger 52-inch fence and long extension table because both allow me more versatility. The 52-inch T-Glide fence gives me more support and accuracy when ripping longer boards, and the extension table is amazing because it gives me a lot of room to stack lumber waiting to be cut. It keeps the wood right at my side, which leads to increased safety and speed.

My SawStop model also came with a really nice mobile base, which is better than any other mobile base that I’ve ever used. It doesn’t slam the machine down, like some other mobile bases do (hint, hint Grizzly company…).

Best Contractor Table Saw

As I mentioned above, a contractor table saw is a good option for a budget-conscious woodworker who needs to save space, have portability, but still needs a table saw with a descent amount of power. Here are my top choices for the best contractor table saw.

SawStop 10-inch Contractor Table Saw

By far the most popular contractor table saw on the market (and the safest), is the SawStop contactor table saw. This portable table saw boasts 1-3/4 Horse Power, which is as much power as some larger cabinet table saws. This portable table saw comes in three different configurations:

- SawStop Model CNS175-SFA30 contractor table saw: This model costs around $1,699 and comes with a basic aluminum fence and has a 30-inch tip capacity (pictured above).

- SawStop Model CNS175-TGP236 contractor table saw: This model costs around $1,899 and comes with an upgraded Pro T-Glide fence system (which I really like) that allows a 36″ rip capacity. It also has an upgraded rip fence.

- SawStop Model CNS175-TGP252 contractor table saw: This model costs around $1,999 and also comes with an upgraded Pro T-Glide fence system, but has a very wide 52″ rip capacity. It also has an upgraded rip fence.

You can shop for one of these contractor table saws at the below stores:

- Buy the SawStop Contractor table saws at WoodCraft

- Buy the SawStop Contractor table saws at Rockler

- Buy the SawStop Contractor table saws at Highland Woodworking

Here are some other somewhat popular contractor table saw options, but please note that they do not have the flesh-detecting brake technology (or as positive reviews):

Powermatic 64B 10-inch contractor table saw

The Powermatic 64B is probably the next most popular contractor table saw, and it features a 1.75 Horse Power motor and 10-inch saw blade. This contractor table saw comes in two versions. From what I can tell, the only difference is the rip capacity. One has a narrower table, which allows a 30-inch rip cut and the other model offers a wider table for a 50-inch cut:

- Powermatic 64B 10″ Table Saw with 30-inch fence:

- Powermatic 64B 10″ Table Saw with 50-inch fence:

As I’ve mentioned in other articles, Powermatic used to be considered one of the top brands for consumer table saws, and their machinery was made in the U.S.A. But after outsourcing their manufacturing to Taiwan, the quality control has apparently dropped, according to friends of mine and many online forums. But the prices haven’t dropped. Apparently Geetech Chiu Ting Machinery Company in Taiwan (may also have factories in China) now manufactures most brands of table saws, including Powermatic, JET, Grizzly, Laguna, Oliver, Rigid, Delta, DeWalt and even SawStop. But it appears that each company can specify different levels of quality control (QC) and engineering. And Powermatic apparently dropped the ball on their QC. Powermatic contractor table saws are more expensive than the SawStop contractor table saw (mentioned above) but have more problems. So buyer beware.

Shop Fox W1837 10-inch Contractor Table Saw

The Shop Fox W1837 table saw is another portable table saw option for woodworkers. This table saw is priced right around the SawStop contractor table saws, but features a 2HP motor. I’m not sure if you’ll notice any difference, but it’s worth considering. The rip capacity on this saw is 30-inches.

- Shop Fox W1837 table saw:

JET 1-3/4HP ProShop II Contractor Table Saw

From what I can gather, JET machines are now made in the same factories as most other table saws on the market, but the price point is a bit lower than Powermatic, along with features. Here are a few iterations fo the JET ProShop II contractor table saw:

- JET ProShop II Table Saw with 30-inch rip capacity and stamped steel wings (inferior) 115V:

- JET ProShop II Table Saw with 52-inch rip capacity and stamped steel wings (inferior) 115V:

- JET ProShop II Table Saw with 30-inch rip capacity and cast wings (superior) 115V:

- JET ProShop II Table Saw with 30-inch rip capacity and cast wings (superior) 230V:

- JET ProShop II Table Saw with 52-inch rip capacity and cast wings (superior) 115V:

Best Jobsite Table Saw

SawStop Jobsite 10-inch table saw

The most popular (and also most safe) jobsite table saw is the SawStop Jobsite Model JSS-120A60 1-1/2 HP table saw pro with mobile cart assembly. You can buy this portable SawStop jobsite table saw at these stores:

- Buy the SawStop jobsite table saw at Amazon

- Buy the SawStop jobsite table saw at WoodCraft

- Buy the SawStop jobsite table saw at Rockler

- Buy the SawStop jobsite table saw at Highland Woodworking

The great thing about this portable table saw is that it is easily folded up onto it’s mobile base so it can be toted from your truck to your jobsite. Here I’ll share some other popular jobsite table saws, in case the SawStop jobsite table saw is beyond your budget. Just be aware that none of these other portable table saws have the proprietary safety saw brake that the SawStop table saws have:

BOSCH 4100XC-10 10-inch jobsite portable table saw:

I’m partial to tools made by Bosch, as I’ve used them quite a bit before. A few years ago I was excited when Bosch released a jobsite table saw called the Bosch Reaxx table saw, with similar flesh-detecting technology as the SawStop table saws (see this video of a guy touching the Bosch Reaxx table saw blade). However, the U.S. International Trade Commission found that Bosch had violated patents held by SawStop. So Bosch returned back to this version of the jobsite table saw. Kudos for them trying to make a safer table saw. But this jobsite table saw is still really nice. It also has a 15 amp motor, with a 30-inch rip capacity. This table saw also has nice storage compartments for safety attachments & the power cord. It runs about $600.

DeWalt DWE7491RS 10-inch jobsite portable table saw:

The Dewalt DWE7491RS is certainly one of the most popular jobsite table saws, partly because of the reliability, and also because of the lower price (about $600). This table saw doesn’t have as strong of a motor as the SawStop jobsite table saw, but the 15 amp motor will cut most softwoods and thinner hardwoods without much trouble. It has a 32-inch rip capacity and a nice rolling stand.

SKILSAW SPT99-11 10-inch jobsite portable table saw:

The Skillsaw SPT99-11 is another highly rated portable table saw for jobsite work. It is quite similar to the Dewalt DWE7491RS table saw. It also comes with a nice rolling stand. The saw and stand run about $650.

DeWalt DWE7485 8-1/4 inch jobsite compact table saw:

If you’re on a really tight budget, but you still want a table saw, then this bench top style jobsite table saw may be a good option for you. This Dewalt DWE7485 compact jobsite table saw runs about $350. It has a similar motor power to other jobsite table saws (15 amps) but it does lack in other areas, to keep costs low. This table saw has a smaller saw blade (8.25″ vs. 10″) which will limit you to thinner board thicknesses. It also has a very limited rip size of 24″, if you’re wanting to use a fence. It also doesn’t come with a stand, so you would need to find a way to support this table saw, or kneel on the ground to use it. But it does have a lot of satisfied customers. You can read the reviews here:

On page 2 I’ll continue this table saw buyer’s guide by talking about table saw blades, push sticks, and other table saw accessories:

Continue to page 2/2: Buying Table Saw Blades and Accessories:

Page: 1 | 2

* Disclaimer: Affiliate links may be posted in this article for your convenience in choosing tools. By using these links it provides support for our website at NO COST TO YOU. By purchasing anything through the links (even other products not listed) you help support the production of more quality content. But unlike many others, we don’t suggest products unless we have used them or have thoroughly investigated them.