By Joshua Farnsworth

In the above video I introduce a cool new table saw accessory that SawStop sent to me: the SawStop Folding Outfeed Table. I used to use a large wooden outfeed table in my former workshop, back when I didn’t need my woodworking machines to be mobile. But since remodeling & moving into my new dream workshop (and starting my woodworking school), I’ve meant to build a wooden folding outfeed table, so I could fold the table out of the way when classes were being held. But I just haven’t had time, so I’ve made do with an inferior alternative: using roller stands like this:

While they work, roller stands can be a pain in the butt. Especially when ripping long and heavy boards. And they don’t work very well to support my cross cut sled when it extends over the edge of the table saw. An outfeed table works much, much better. Especially when ripping long & heavy boards, cutting sheet good, and using a cross cut sled.

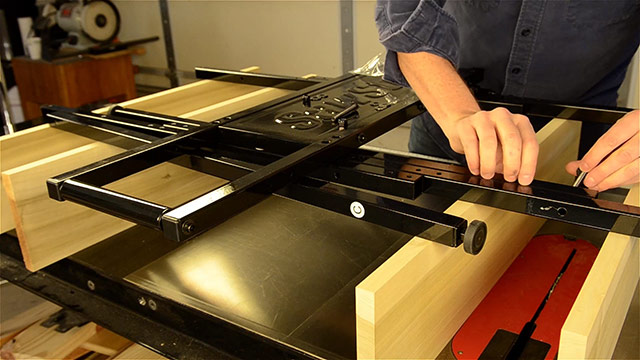

So I was excited to receive this sturdy metal outfeed table in the mail a few weeks ago. And since I know how much everyone hates trying to decipher assembly instructions (although SawStop’s are much better than any others), I thought I’d film the process to aid anyone out there who plans on buying & assembling their own folding outfeed table.

These instructions are for my specific SawStop table saw model & accessories (see my model here), so you should still refer to your user manual for any variations for your model. But I think my video will be a nice visual reference regardless of your model of SawStop table saw.

As you can see here, this folding outfeed table has a very low profile when it is folded down:

Why Did I Buy a SawStop Table Saw?

About 5 years ago I bought a SawStop cabinet saw, and I did it primarily for safety reasons. In case you don’t know, SawStop table saws have a patented technology to stop the saw blade, in a fraction of a second, if it detects flesh (or a hot dog…). This was one of the few tools that my wife supported me in buying. She was supportive because a close friend told us how his neighbor (an experienced woodworker) had lost several fingers in a table saw accident.

But I also feel that SawStop table saws are one of the most well made and best engineered table saws on the market. You can read my table saw buyer’s guide page (here) for more details about the SawStop cabinet saws, and you may also enjoy watching this video that the Discovery Channel did on the SawStop table saw technology:

SawStop Table Saw Models:

As a reference, and in case you’re thinking of buying a SawStop cabinet saw or SawStop contractor saw, in order of most expensive to least expensive, here are the different models and feature combinations for you to check prices on (the affiliate links lead to the product pages on Amazon):

- SawStop ICS5123052 5Hp Industrial Cabinet Saw 52″ Ind Fence System

- SawStop ICS31230-52 3Hp Industrial Cabinet Saw 52″ Ind Fence System

- SawStop PCS31230-TGP252 3-HP Professional Cabinet Saw Assembly with 52-Inch Professional T-Glide Fence System, Rails and Extension Table (this is the model and package that I own)

- SawStop PCS31230-PFA30 3-HP Professional Cabinet Saw Assembly with 30-Inch Premium Fence System, Rails and Extension Table

- SawStop PCS175-TGP236 1.75-HP Professional Cabinet Saw Assembly with 36-Inch Professional T-Glide Fence System, Rails and Extension Table

- SawStop PCS175-PFA30 1.75-HP Professional Cabinet Saw Assembly with 30-Inch Premium Fence System, Rails and Extension Table

- SawStop CNS175-TGP36 1.75Hp Contractor Saw 36″ Prof T-Glide Fence System

- SawStop CNS175-SFA30 1.75Hp Contractor Saw 30″ Aluminum Fence System

- SawStop JSS-120A60 1.5HP Jobsite Saw PRO with Mobile Cart Assembly

If you plan on cutting thick hardwoods, then look at cabinet saws with at least 3HP. If not, then any of the other models will work.