How to Choose the Best GreenWoodworking Tools

A Woodworker’s Guide for Choosing the Best GreenWoodworking Tools, including axes, carving knives, froes, shaving horses, etc.

![]() By Joshua Farnsworth | Updated Mar 01, 2022

By Joshua Farnsworth | Updated Mar 01, 2022

How to Choose the Best GreenWoodworking Tools

A Woodworker’s Guide for Choosing the Best GreenWoodworking Tools, including axes, carving knives, froes, shaving horses, etc.

![]() By Joshua Farnsworth | Updated Mar 01, 2022

By Joshua Farnsworth | Updated Mar 01, 2022

Disclosure: WoodAndShop.com is supported by its audience. When you purchase through certain links on our site, we may earn a small affiliate commission, at no cost to you. Learn more.

Introduction to Buying GreenWoodworking Tools

By Joshua Farnsworth

Greenwoodworking with woodworking hand tools is an incredibly fun method of woodworking, because you get to use fresh, wet wood, and start transforming it into rustic furniture (and downright elegant, in the case of Windsor chairs) without having to wait for it to dry. And the wood is often free!

Which Woodworking Hand Tools Do You Need for GreenWoodworking?

A lot of woodworkers want to know which hand tools they need for working green wood. So I’ve written this greenwoodworking tool guide to help you out, with the input of a few friends.

First you can watch the video at the top of this page where Mike Cundall broadly introduces different green woodworking tools, along with some of his beautiful carved wooden bowls and wooden spoons. And below the video you’ll find the buyer’s guide article for greenwoodworking hand tools.

GREENWOODWORKING HAND TOOLS BUYER’S GUIDE

Make a Shave Horse

What is a Shave Horse?

A shave horse (or shaving horse) is a bench with a foot-operated vise. It is basically the green woodworker’s workbench. You stick the piece of green wood into the jaws, and your foot pressure will hold the wood tightly.

What to look for in a Shave Horse?

Different people prefer different styles of shaving horses for greenwoodworking. Here are some different styles that I’ve photographed over the years, to give you some inspiration:

The dumbhead (or swinging vise) can either be made from a log, or from laminating boards together. My kids love being able to use the word “dumb head” without facing retribution.

The main consideration is that the angle of the ramp is comfortable for you to work with, and that the dumb head clamps your work tightly. Oh, and that the legs don’t break!

Where to find a Shave Horse for GreenWoodworking?

The best shave horse is one that you’ve made yourself. Yes, there are some that you can buy, but it’s a pretty simple project to build. You can find plenty of plans & videos online, and you can also take the popular class at our school: “Build a German Shave Horse with Ervin & Willie Ellis”. Here’s a little video that the Ellis brothers filmed in my school:

(here’s the accompanying blog post).

But as you can see in these photos, a shaving horse doesn’t have to be perfect:

This shave horse was still being built when I photographed it, but you can see how rustic a shaving horse can be to get started shaving green wood.

Most people who own a shaving horse made it themselves. There are a lot of plans and tutorials online and in woodworking magazines for building a shave horse. Since it’s not difficult to build a shave horse, there are not a lot for sale. Lie-Nielsen used to sell a shave horse, but they were quite costly (nearly $1,000 if I remember correctly), so they discontinued them (due, I’m sure to a major lack in sales). You can build one for $15, and they’re a fun weekend project, so I’m not sure a lot of people would pay $1,000. I did manage to find one for sale on Etsy (here), and a shave horse kit (here). But I’d recommend to go build one!

Buy a Drawknife

What is a Drawknife?

A draw knife is a very useful tool for both rough cuts, to break down green wood into a rough shape, and for refining cuts. It’s the main tool used on a shave horse. The woodworker holds both handles, and pulls the drawknife toward their body, shaving wood off the workpiece.

What to look for in a Drawknife?

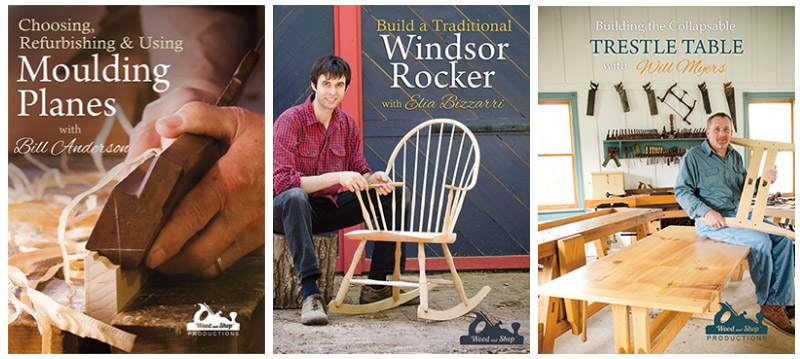

Different people have different preferences when it comes to drawknives, but Windsor Chair maker Elia Bizzarri prefers a drawknife that tapers slightly toward the cutting edge. He said that a thinner blade offers the ability to get a shorter blade bevel, which means it will get into concave surfaces more easily. He said that this feature isn’t so important for shaving chair spindles, but more so for the curved surfaces of a windsor seat.

Elia said that a drawknife can be used either bevel down or bevel up, but he prefers to use it bevel down. But if using a drawknife with the bevel up, the back can’t be dead flat, but needs to be slightly rounded, so that the drawknife won’t get stuck, and can come up out of the cut. If you prefer using it bevel down (like Elia), then a flat back is prefered. This makes sharpening easier.

The desired handle angle also depends on if you choose to use your drawknife bevel down or bevel up, because you want your wrist to be straight when working. So, for example, if you found a drawknife at a flea market, and you wanted to use it bevel down, you could sit in a chair, hold it out in front of you at waist height, and see if the handles allow you to keep your arms straight when the bevel is down.

Here’s a great article by Curtis Buchanan called, “How to Sharpen and Use a Drawknife” (Fine Woodworking issue #268). By the way, Elia Bizzarri apprenticed under Curtis Buchanan.

Where to find a Drawknife?

There are a few modern tool companies who make drawknives, but antique drawnives they can be found at quite reasonable prices if you hunt around at flea markets, yard sales, or antique stores. Drawknives were a more common tool, that was used extensively on farms. Below are some ideas of where to find antique and new drawknives:

- The first place to find antique drawknives is at farm sales, estate sales, flea markets, antique stores. But if you don’t have time to hunt them down that way, try buying online:

- Search antique drawknives on Ebay

- Search new drawknives on Highland Woodworking (this is the best selection of new drawknives)

- I looked at a lot of drawknives on Amazon, and they didn’t appear to meet the standards for a good draw knife.

Buy 1-2 Spokeshaves

What is a Spokeshave?

A spokeshave is basically a small handplanes used for shaping and smoothing curved wood. The spokeshave body holds an adjustable blade rigidly against the bed, in a very similar way to a handplane. As mentioned above, spokeshaves were originally used for making wagon wheel spokes, but have moved into being used for other types of woodwork.

What Spokeshaves Do You Need?

Opinions vary on which spokeshaves you need for woodworking, because many people use spokeshaves for different tasks. I will try to explain which spokeshaves excel at certain types of work, and then you can make the decision about which spokeshaves to buy.

I like to have at least two spokeshaves, one with a flat bottom and set for taking more of a rough cut, and and one set for fine cuts. The fine cut spokeshave can have either a flat bottom, or (as I prefer) a slightly rounded bottom, for getting into curves. Many of the modern budget-friendly spokeshaves have poor machining, don’t have a bed that’s flat enough for stability, and don’t have good tool steel for the iron. There are a couple modern spokeshaves that can be modified to work well, especially with a good replacement blade that will hold a nice edge.

What are the Best Vintage Spokeshaves?

{photo of wooden spokeshave}

Antique spokeshaves are usually my preference, and antique wooden spokeshaves are really sweet if you can get them tuned up and get a tight mouth. However, before buying antique wooden spokeshaves, make sure the wooden body isn’t split. A couple people have done pretty good tutorials on how to sharpen wooden spokeshaves (check YouTube).

My favorite vintage, all metal spokeshave is the Stanley No. 151 spokeshave (also manufactured as the Record A151 spokeshave). It is probably the most popular and best-designed spokeshave. Hand tool expert Jim Bode said of the Stanley 151 spokeshave:

“The best-selling spoke shave of all time. A totally no-nonsense shave with dual micrometer like adjustments that allow you to take thin shaving on one side and a heavier cut on the other, if you want to. Easy to sharpen and easy to find replacement blades. Works great on flats, convex, and even concaves greater than 8 inch radius.”

Another very popular, though not as easily adjustable spokeshave is the vintage Stanley No. 51 spokeshave (pictured below). If tuned up, these smaller spokeshaves work great, and are cheaper than the No. 151.

Back in the October 2002 issue of Fine Woodworking Magazine, chairmaker Brian Boggs wrote a great article titled, “Soup Up Your Spokeshave” that should be helpful in making your vintage (or even new) spokeshave work as good as possible (find the article here).

- Here are some excellent vintage spokeshave models that should be easy to find:

- View Stanley No. 151 spokeshaves on Ebay

- View Stanley No. 51 spokeshaves on Ebay

- View Record A151 spokeshaves on Ebay

- View new Stanley No. 151 spokeshaves on Amazon

- Here is an Ebay search for used spokeshaves that have sold, so you can get an idea of the current going price for different models.

What are the Best New Spokeshaves for Woodworking?

A well-respected chair maker, Brian Boggs, designed an excellent curved-bottom spokeshave for Lie-Nielsen. This is my favorite new spokeshave. The A2 blade keeps a good edge and the castings are nicely machined with a flat bed and cap iron, which all lead to a chatter-free tool that helps prevent tearout. The hickory handles are comfortable and appropriately shaped. The Lie-Nielsen spokeshave comes totally tuned, sharp, and ready to use out of the box. You can buy it here.

Cheaper, new spokeshaves are rarely usable out of the box. But as mentioned earlier, here’s an excellent Fine Woodworking article by Brian Boggs, called “Soup Up Your Spokeshave” where he shows how to improve a newer, cheaper spokeshave (Issue #158, pp. 45-49).

Stanley has manufactured a “reproduction” of their vintage No. 151 spokeshave (pictured above). Though not made as good as the original (maybe they lost the recipe?) with some work and modifications it can do a pretty good job. You can also use your belt sander to round the bottom. You can find it on Amazon here. (sold under model numbers 12-951 and 1-12-151 for $25-$35). But it’s going to require just as much work (if not more) than a vintage No. 151, so you might as well buy a vintage model and put some work into it, and get a better spokeshave.

Other new Spokeshave options: Highland Woodworking has a good selection of new spokeshaves and replacement blades here. I have heard good things about the Veritas Low Angle Spokeshave, found at the above link. I would steer clear of the Kunz spokeshaves, as I haven’t had luck tuning them up.

RELATED

Which 20 Woodworking Hand Tools Should You Buy First?

Why Traditional Hand Tool Woodworking?

10 Jaw-Dropping Woodworking Shop Tours

57 Page Moravian Workbench Plans Now for Sale

How to Make a Mortise and Tenon Joint with Woodworking Hand Tools

8 Steps to Cutting Dovetails with Woodworking Hand Tools

Buying Carving Hatchets

What is Carving Hatchet?

“This is a small axe or hatchet designed for carving purposes as the name implies. They tend to sit somewhere in size between a boy’s axe and camp hatchet. Often the leading edge is radiused to promote cutting. This isn’t necessary. Carving hatchets come either single or double-beveled. Double bevel axes/hatchets are what you would typically find. The cutting edge is the result of two equivalent bevels meeting to form an edge. A single-bevel is designed to be flat on the one side, while the other retains a bevel. This arrangement reduces the angle of attack for the hatchet while in use. It is moving on a more nearly vertical plane. Either arrangement of bevel is suitable for carving. Once one is practiced, it only takes a little adjustment to work from one style to the other.” (Mike Cundall)

What to look for in a Carving Hatchet?

“As with any edged tool look for quality steel, good edge geometry, and a solid handle. The hatchet should feel good in the hand. Practice and use will help determine your preference.” (Mike Cundall)

Peter Follansbee has a good article on choosing hatchets for spoon carving (here).

Where to find good Carving Hatchets?

“Hatchets of this sort are more commonly found than adze. The makers listed on the entry for adze also hold here, but there there are far more hatchets out there. Gränsfors Bruks, Wetterlings are good makers, But camp axes from companies like Stihl and such would also suffice.” (Mike Cundall)

In his great article on buying hatchets & axes, Robin Wood (accomplished spoon carver and bowl carver) says that if he were to only have one axe, it would be the “Gränsfors Bruks Swedish carving axe” (find it here). However, he admits the drawbacks are its price and that it may be too heavy for a lot of people. So he recommends (as do I) a lighter and more affordable carving hatchet: The Gränsfors Bruks Wildlife Hatchet (find it here). (See all of the Gränsfors Bruks axes & hatchets here).

*Please note that Gränsfors Bruks acquired the struggling Wetterling Axe company in 2016, and Wetterling axes are no longer in production. So the only source I know is in the used market.

- Here are used (and a few new) Wetterling axes on Ebay

- Here are Gränsfors Bruks hatchets & axes on Ebay

- Here are single-bevel axes/hatchets on Ebay

- Robin Wood, along with his now famous daughter JoJo Wood, recently released a carving hatchet that they designed. With shipping from the UK it runs about $93. (You can find it here).

Buying Axes

What is it an Axe?

“An axe is typically thought a larger version of the hatchet primarily used for the felling and bucking (delimbing) of trees. There are as many styles designs of axes as there are stars in the sky. For green woodworking, the axe is typically used to get the wood pieces to a manageable and usable rough state, though a saw is used for final cutting. The axe is used, or often a maul (a splitting axe) to help split or rive the wood while it’s in the round shape.” (Mike Cundall)

What to look for in an Axe?

“As mentioned above, look for a good head, made from decent steel, and a handle in good shape. A serviceable axe is easy to find new or used. Be sure to check the head for chips, nicks, possible cracks, or a mushroomed poll (the back end of an axe head opposite the lead edge).” (Mike Cundall)

In this video Bushcraft & Survival expert Ray Mears explains the differences between different sizes of axes, and how to use them:

Where to find a good Axe?

“Axes are not difficult to find. There are a variety of types, grades, and makers. A serviceable axe can be had from the local home center. There are others from companies like Gränsfors Bruks and Wetterlings.” (Mike Cundall)

The size and type of axe that you need, will largely depend on what you intend to use it for, and also your level of strength. As mentioned in the carving hatchet section, you would choose a small carving hatchet if you planned to do detailed carving. If you are interested in felling a tree, then a Felling Axe would be appropriate. If you want a multi-purpose axe that is useful for cutting limbs and sizing logs for bowl carving, then a small forest axe would work best. Ray Mears favors the small forest axe for it’s portability & light weight, yet ability to use with two hands.

If you want a brand new, sharp, and ready to go axe, then I’d recommend the following:

- Gränsfors Bruks Small Forest Axe

- Gränsfors Bruks American Felling Axe

- See other sizes of Gränsfors Bruks axes here at Amazon

- See other sizes of Gränsfors Bruks axes & hatchets at Highland Woodworking).

But if you don’t mind putting a little work into getting a vintage axe ready, I would recommend buying an old single bit axe head (2-4 lbs.) on Ebay, and add your own handle. I personally use a vintage Collins single bit axe head (3 1/2 pound), which is an average size, good for tree limbing and splitting firewood. Expect to pay $15-$40 for a good vintage single bit axe head. Here are some good, common brands to search for:

- Collins single bit axe head

- Plumb single bit axe head

- True Temper Kelly single bit axe head

- Master Mechanic single bit axe head

- Craftsman single bit axe head

- Winchester single bit axe head

- There may be other good brands, so search here for sold single-bevel axe heads to get an idea of which vintage brands are popular and their going price.

- Steer clear of the really expensive collectible axe heads. They are expensive because of their rarity and interesting features.

Buy a “Slöjd Knife” (i.e. Straight Carving Knife)

What is a “Slöjd” Carving Knife?

“Often called Slöjd knife (Sloyd kinfe), this knife is a basic tool with a distinctive shape. Used to carve anything from spoons, to bowls, to handles. It does well to rough carve, when used in the proper way, and to put finishing touches on projects, if suitably sharp and well maintained. These sorts of knives are utilitarian, but are not meant for rougher work that one might see fit with say a camp knife (like splitting and riving small branches, etc).” (Mike Cundall)

*Who was Slöjd and what was so special about his knife?

What to look for in a Straight Carving Knife?

“Look for good steel and handle that feels good in the hand, ovaloid in shape. The edge bevels should be the same thickness down the entire length of the blade. The blade is typically straight with no radius.” (Mike Cundall)

Where to find a good Straight Carving Knife?

“One of the most well known and inexpensive makers is Mora. The famous Mora-Knife (Morakniv) would do any beginning or experienced carver well. There are a number of smaller makers out there. This sort of knife is not hard to source“. (Mike Cundall). You can buy the Swedish Morakniv 106 Straight Knife on Amazon, here. This is also Robin Wood’s preferred straight knife, which is good, because it’s only about $25 with shipping.

Buy a Hook Knife (i.e. “Spoon Carving Knife”, i.e. “Crook Knife”)

What is a Hook Knife / Spoon Carving Knife?

“This knife, as the name implies has a hooked profile useful for making the concavities in spoons, kuksas, and other small bowls. This is a specialty knife mostly found accompanying spoon carvers. The radius for any spoon knife varies. Some have a compound radius while others are simple.” (Mike Cundall)

What to look for in a Hook Knife / Spoon Carving Knife ?

“Good steel, good bevel, edge durability, and comfort of feel in the hand.” (Mike Cundall).

Hook knives come with different radius curves. Beginners find shorter blades with tight curves easier to start with, but it doesn’t leave as fine a surface as a less tight curve. But the more open radius leaves a nicer finished cut, but takes some time to get the hang of. Ideally you should look for a hook knife that has a

Where to find a a good Hook Knife/ Spoon Carving Knife?

“Mora makes a good hook knife as do a lot of other smaller makers. These knives are not hard to source.” (Mike Cundall)

Robin Wood has used around 50 different brands of hook knives in his classes, and wrote a great article called, “Which is the best spoon carving knife, hook knife?“. I will defer to his article on the best hook knives. But, like Mike, Robin mentions that the Mora hook knives are acceptable (especially the #164). Here are a few readily available sizes on Amazon:

- Morakniv Wood Carving Hook Knife (Model #164: 0.5-Inch Internal Radius)

- Morakniv Wood Carving Hook Knife (Model #162: 0.6-Inch Internal Radius)

- Morakniv Wood Carving Hook Knife (Model #163: 0.9-Inch Internal Radius)

If you don’t have time to read his article, he mentioned these as his favorite brands (some may be hard to find):

- Svante Djarve spoon knives

- Ben Orford hook knives

- Hans Karlsson’s hook knives

- Del Stubs’ hook knives at Pinewood Forge

- Bo Helgesson hook knife (his favorite)

- Robin Wood’s new hook knives

Buying Carving Gouges

I’ve written an extensive guide on carving gouges, so head over to our buyer’s guide for Wood Carving tools (specifically wood carving gouges) here:

Buying or Making Splitting Wedges

What is a Splitting Wedge?

A splitting wedge (i.e. a “glut”) is simply a wedge shaped piece of metal or wood, used for splitting logs.

What to look for in a Splitting Wedge?

When splitting logs, I like to use a combination of metal splitting wedges (which are smaller), and larger home-made wooden wedges. The metal wedges are good for starting the split in the log, and I love the large wooden wedges for expanding those initial splits.

When making wooden wedges (or gluts), it’s best to make it out of a very hard and dense wood, such as dogwood, hickory, ash, oak, etc.

For metal splitting wedges, I prefer to find one with a flared head (like a nail head). When I split logs, I’ve noticed that this style offers more surface area for the sledge hammer, so the metal wedge doesn’t fly out of the log as easily. But it’s kind of hard to find that style of metal wedge from a modern manufacture. So keep your eyes open at flea markets and yard sales.

Where to find a Splitting Wedge?

You can find your wooden wedges in the forest. Just cut some 3-4-inch diameter green wood into 12-inch lengths (or close). I leave the bark on, and then use a hatchet to put a double taper on the wood. I painted Anchorseal on the wood that I exposed with a hatchet. Strong hardwoods that don’t easily split are better (I made those in the above photo out of Dogwood). But use what you can easily find, and if it gets ruined, then just try a different wood!

Metal splitting wedges can be found in any hardware store, or many places online. Here are some splitting wedges on Amazon…just choose one that fits your budget, and that has good reviews. Just make sure you don’t get the cone shaped splitting wedges, as you need a wide bevel edge to score a split line on the end of your log.

And just make sure you don’t use your wooden mallet to drive the metal wedge in. It will destroy it in short order. Use a sledge hammer to drive these puppies into the log.

Make a Wooden Maul (Wooden Hammer)

What is a Wooden Maul?

A wooden maul is simply a wooden hammer or mallet made out of a small log.

What to look for in a Wooden Maul, and Where to Find it?

A wooden maul can’t be purchased (as far as I’m aware), and is easy to make with a chain saw (or even a cheap pruning saw) and a draw knife. Here are the two sizes that I make:

- A smaller wooden maul used for whacking the back of my froe, for splitting wood (see above). These are often made out of tree roots, because of the hard, unsplitable wood. I used a section of a small dogwood tree (about 6-inch diameter).

- A large, two-handed maul used for whacking my wooden splitting wedges (see below). For this big boy, I also used dogwood, and the diameter was about 8-inches.

Buy or Make a Splitting Froe

What is a Splitting Froe?

A woodworking splitting froe is long, handled wedge used to split wood along it’s grain lines. The froe has a handle that can be pivoted back and forth to control the direction of the wood split.

What to look for in a Splitting Froe, and Where to find one?

There’s not much to a froe. In fact, they are a little hard to find out in the antique market, so don’t be too picky about condition if you find one. Even if you find a split or chips in the metal, you should buy it, if the price is low. It’s not a precision instrument. The blade isn’t meant to be sharp, so you don’t need it to be sharp. Antique froes were usually sitting out in a barn for decades, so the metal will likely be rusted and the handles are likely rotting.

Rehab is easy. Just remove the rust, make a new handle (with a draw knife), and get to work. It’s best to use dry wood for the handle, as a wet green wood will shrink over time, and your handle will slip out. But even a properly made handle will often slip out from time to time. If your handle slips, then you can drill a small hole in the handle, just below where the handle enters the froe. Then pound a dowel through the hole.

Where to buy a vintage Froe:

- As I mentioned above, antique froes are a little hard to find locally, but you can try visiting flea markets, antique shops, and tool sellers. But they are quite plentiful and affordable on Ebay (here).

Where to find a new Froe:

- This forged froe is made by a blacksmith in Slovenia (Rovtar Forge). He made my bowl adze, and has really great online reviews.

- Highland Woodworking sells several splitting froes (here)

- Lie-Nielsen sells a froe (here). It’s not as nice as a blacksmithed froe, but it’ll do the job.

- You’ll also find new splitting froes on Ebay (here).

Make your own Froe:

- A lot of people forge their own froe from a car leaf spring. I haven’t done this, but I’ve heard that it’s a simple blacksmithing project, since the leaf spring is basically the same shape as a froe.

Buying T-Handle Augers

What is a T-Handle Auger?

A T-handle auger is basically a big human-powered auger, or drill bit. It is used a lot in green woodworking, especially for boring holes for splayed legs and mortises.

What to look for in a T-Handle Auger?

T-handle augers come in a lot of different hole sizes. Don’t buy one until you actually have a project planned, and you know which size of hole you want to bore.

The two main problems that I find with T-handle augers, is split handles, and blunt lead screws (pilot screw). A broken handle can be replaced, the cutting spurs can be sharpened (only file the inside edges of the spurs, or you’ll modify the hole cutting size), but a blunt lead screw (like the auger on the right, in the photo below) can’t be easily sharpened (it takes a lot of time with a small needle file). So the only deal breaker for me would be a blunt lead screw. But if the auger is free or super cheap, and you’ve got the time and patience, here’s a tutorial on how to sharpen lead screws.

Where to find a good T-Handle Auger?

I’ve actually had pretty good luck finding antique T-handle augers out in the wild for pretty low prices. So look around at farms, flea markets, tool swaps, or antique stores (but they’ll overcharge you). Ebay has a huge source (search for them here). Just make sure the seller has close up photos of the lead screw…or ask them to send you a photo. You can also find some newer augers, but they’re usually more expensive than old ones. I do like the look of the Eye augers that allow you to just put a branch through the hole (like this one).

Buy a Bowl Adze

What is a Bowl Adze?

“An adze is an axe like tool where the cutting edge is perpendicular to the handle, whereas an axe’s edge is parallel to the handle line. Adze have been used for thousands of years to shape wood. Some edges of adze are straight (often seen in a foot adze for ship building). Or they are convex. The bevel for the edge may be on the inside or concavity of the edge or on the outside or convexity. This arrangement is also known as in-canel, or out-canel respectively. There are as many styles of adze as there are makers. In Japanese carpentry the adze is called a chouna and the handles are often grown from a branch to a specific shape. As with any tool, practice and a sharp edge will be enough to achieve good results.” (Mike Cundall)

What to look for in a Bowl Adze?

“As with any edged tool, look for one that feels good in the hand, is made from steel that maintains an edge and is sharpenable. For hewing work, a flat, straight, or slightly cambered edge is best. For creating concavities a convex edge with bevel on the convexity side is best. The handle can be short or long depending on use. Chairmakers adze for seats can have a longer handle.” (Mike Cundall)

Where to Find a Good Bowl Adze?

“There are a number of makers of adze out there. It’s also a bit difficult to find one in flea markets. Larger makers like Pfiel, Hans Karlsson, and Svante Darv are good. There are a variety of smaller boutique makers like Jason Lonon, Paul Pinto, Nic Westermann, etc. At the time of writing good adze may take a while to obtain. But if you know a smith who would be willing, you can get enough pictures to get a good working model.” (Mike Cundall)

Here’s a great, in-depth article by World-renowned bowl carver, David Fisher, on what to look for in a bowl carving adze. Here are links to where you can find the bowl carving adze brands mentioned above (some may be temporarily out of stock):

- Hans Karlsson Bowl Adze

- Svante Darv Bowl Adze

- Pfiel Bowl Adze

- Jason Lonon Bowl Adze

- Paul Pinto Bowl Adze (about $190 w/ tax + shipping)

- Nic Westermann Bowl Adze

- Rovtar Forge in Slovenia (about $124 w/ shipping…I just ordered this, and am excited to try it out)

Buying a Foot Adze

What is a Foot Adze?

A Foot adge has a long handle, and is meant to be used with two hands to flatten green timber, while standing above it (watch out for your feet!). They were traditionally used for squaring up timber for buildings or for ship building. It’s kind of like a scrub plane with a handle.

What to look for in a Foot Adze?

A lipped foot adze makes for a cleaner cut, as there are no sharp corners to dig into the surface that you’re flattening. Here’s an English bloke, named Sean Hellman, demonstrating how to use a foot adze:

Where to Find a Good Foot Adze?

Where to buy a Vintage Foot Adze:

A foot adze will be quite difficult to find locally, but you can usually find some good antique adze heads on Ebay or from antique tool dealers. Look for a “foot adze”, “shipwright adze”, or “hewing adze”. You usually will have to buy or make a handle. And honestly, it’s a bit difficult to find a new foot adze. You could probably find a blacksmith to make one for you.

Where to buy a New Foot Adze:

- Gränsfors Brucks of Sweden manufactures some foot adze, but they are hard to find in stock anywhere.

- Highland Woodworking has some new adzes.

Buying Green Wood Marking Pencils

One great “tool” for green woodworkers are these colored pencils from Lee Valley / Veritas. They are excellent for drawing on wet green wood, which normal pencils don’t do so well.

Other specialty Green Woodworking Tools:

- Lathe & wood turning tools

- Chair Travisher (here and here)

- Steam box

- Sledge Hammer

- Traditional bench tools (scrub plane, bench planes, marking & measuring tools, etc…see our other buyer’s guides)

- Brace & auger bits (read our buyer’s guide on Hand Drills, Braces & Drill Bits)

- Tenon cutters (here, here, and here)

- Reamers (here and here)

- Logging crosscut saw

- Barn Beam Boring machine / Barn drill

Continue to the Buying Guide for Wood Clamps, Wood Glue, and Fasteners (#11)…

TOOL GUIDE SHORTCUTS:

HAND TOOL BUYER’S GUIDES

- Intro to Buying Woodworking Hand Tools

- Workbench & Tool Storage

- Layout, Marking, & Measuring Tools

- Handplanes

- Handsaws

- Chisels

- Sharpening & Honing Supplies

- Mallets & Hammers

- Hand Drills, Braces, & Bits

- Tools for Curved Work

- Tools for Green Woodworking

- Woodworking Clamps, Gluing & Fasteners

- Tools for Wood Carving

- Products for Wood Finishing, Sanding & Scraping

- Wood Turning Tools & Lathes

Barr Specialty Tools, barstools.com, Idaho, has a “hewing adz (ship carpenter’s adz)” that may appeal, for $215.

under shave horses the dude wearing the red shirt that bench was made using dimensional lumber curious how the hind legs are attached..any info on this type?

You can email Elia Bizzari through his website to ask him (he’s the guy in the red shirt): http://handtoolwoodworking.com/contact/

Great, comprehensive article…Thanks. Have you been pleased with your adze from rovtar forge? I was looking at buying one or waiting for Jason Lonon to have more available. Appreciate your advice

Thanks Ken! Yes, the adze is great. The handle is a bit skinny, but you may be able to ask the seller to make it a bit thicker. No need spending double waiting for Jason.

I’ve just gone round in a circle looking for an explanation of which gouges to use for turning green wood. This isn’t info that’s easy to locate on the interwebs, and it seems like it would fit in with your categories of green wood working tools or wood turning tools.

You don’t need special turning tools for green wood. Any turning tools should work for green or dry wood.