How to Choose Hand Saws for Wood Working

Which Hand Saw for wood working do you need for getting started? Joshua talks about the Best Woodworking Hand Saw, Back Saw, Dovetail saw, Tenon Saw, and more (Part 1/3)

How to Choose Hand Saws for Wood Working

Which Hand Saw for wood working do you need for getting started? Joshua talks about the Best Woodworking Hand Saw, Back Saw, Dovetail saw, Tenon Saw, and more (Part 1/3)

Disclosure: WoodAndShop.com is supported by its audience. When you purchase through certain links on our site, we may earn a small affiliate commission, at no cost to you. Learn more.

Introduction to Buying a Hand Saw for Wood Working

At first glance hand saws seem to be simple tools. Heck, they look like they’re just a piece of flexible steel with sharpened teeth and a handle.

But most woodworkers who are new to hand tools quickly get confused when trying to understand which hand saw for wood working they need (or which hand saws), and what all the confusing terminology means. Words like “fleam”, “rake”, “tooth count”, “nib”, and “saw taper” are enough to make someone’s head spin.

But hand saws for wood are indispensable for traditional furniture making, so it’s important to understand the different types of woodworking saws and how to use them. In this article I’ll attempt to simplify everything for you, and help you understand which hand saws you absolutely need to get started, which ones can wait until later, and which ones you probably won’t ever need.

Woodworking Hand Saw Characteristics

Before jumping into the hand saw buyer’s guide, there are four hand saw characteristics that are important to understand, which I’ll cover below: (1) Hand Saw Type, (2) Hand Saw Tooth Shape, (3) Hand Saw Tooth Count, and (4) Parts of Hand Saws.

RELATED

Which 20 Woodworking Hand Tools Should You Buy First?

Why Traditional Hand Tool Woodworking?

10 Jaw-Dropping Woodworking Shop Tours

57 Page Moravian Workbench Plans Now for Sale

How to Make a Mortise and Tenon Joint with Woodworking Hand Tools

8 Steps to Cutting Dovetails with Woodworking Hand Tools

1. HAND SAW TYPES

In my mind I divide the most common traditional woodworking hand saws into three general categories: “Panel Saws”, “Back Saws”, and “Frame Saws”. Below is a brief introduction to each of the three types of hand saws:

PANEL SAWS

“Panel Saws” are hand saws that have a handle and thin flexible metal saw plate with no rigid back or frame. Panel saws have larger teeth and are generally used for quickly rough-cutting boards to length or width. These hand saws were manufactured in very large quantities and are easy to find and usually inexpensive. For clarification, this type of saw is actually just called a “hand saw”, and a “panel saw” is a hand saw that’s short enough to fit into the top lid panel of a tool chest. But to help avoid confusion with the overall category name, I often just call all of these saws “panel saws”.

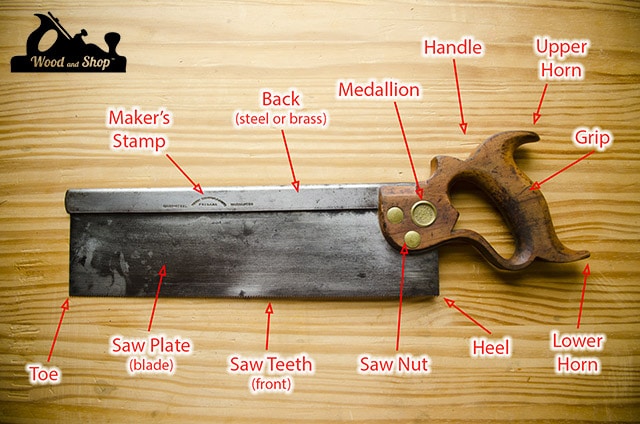

BACK SAWS

Back saws have fine teeth and thin metal saw plates, and are used for making precision wood cuts. They have rigid brass or steel backs to keep the saw plate from bending, which provides rigidity for accurate cuts of wood joints. The smaller the saw teeth, the finer the cut. Historically, back saws were used primarily by joiners and cabinetmakers, and are typically more expensive than normal hand saws.

FRAME SAWS

Frame saws (or “turning saws”) use tension to tighten a blade between two saw arms. When used with a narrow blade, a frame saw works great for cutting curves (similar to a power bandsaw) and can also be used for rough cutting boards and logs when a larger blade is added. Frame saws come in all sorts of sizes, with small teeth for fine work to large teeth for rough-cutting.

2. HAND SAW TOOTH SHAPE

Hand saw blades are usually sharpened to two different tooth configurations, “Rip” and “Cross Cut”. You can change any saw’s tooth shape with saw sharpening tools. There is also a hybrid hand saw tooth configuration that is in between a Rip and Cross-cut shape, called a “Sash” tooth configuration, which is useful if you can only afford one hand saw…but it’s not as proficient at either ripping or cross-cutting). Here are some tooth shape illustrations:

RIP SAW TEETH

CROSS-CUT SAW TEETH

Hand saws with “Rip” teeth will cut along the length of the board with the grain. This is referred to as “ripping” a board. Each tooth is shaped like a woodworking chisel, filed straight across. So the teeth push through the wood like a chisel.

Hand saws with “Cross Cut” teeth cut across the grain. This is referred to as “cross cutting” a board. Each tooth is filed with two angles, to make it shaped like a knife blade, so the teeth can cleanly sever the wood grain, just as if you used a knife.

*TIP: A rip saw can be used to cross-cut a board, and a cross-cut saw can be used to rip a board, but this isn’t an ideal situation if a clean cut is required. This becomes less of a concern when using very small saw teeth, like with backsaws.

3. HAND SAW TOOTH COUNT

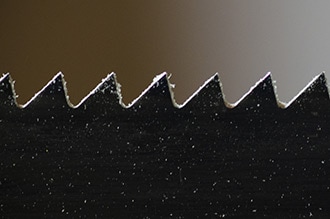

The number of saw teeth per inch (or “points per inch”) is another important factor in selecting a hand saw for a particular purpose. Large hand saw teeth will cut quickly through the wood, but will leave a rough surface. Small hand saw teeth will cut finely and accurately, but are not practical for cutting long lengths or widths. When dealing with normal hand saws or frame saws, “Rip” teeth are typically larger than “Cross Cut” teeth. In back saws, rip and cross-cut teeth can vary in size. The number of teeth per inch are usually expressed as “points per inch” (ppi) or “teeth per inch” (tpi) and the number is usually stamped into the saw plate. PPI is determined by counting from one point to another, and TPI is determined by counting full teeth. PPI is a more common method for tooth count. Also, you can change the tooth count during your sharpening. Here are examples of large (rough) and small (fine) hand saw teeth:

This photo shows a dovetail back saw with rip teeth filed to a tooth count of about 15 ppi.

This photo shows a hand saw with rip teeth filed to a tooth count of about 5 ppi.

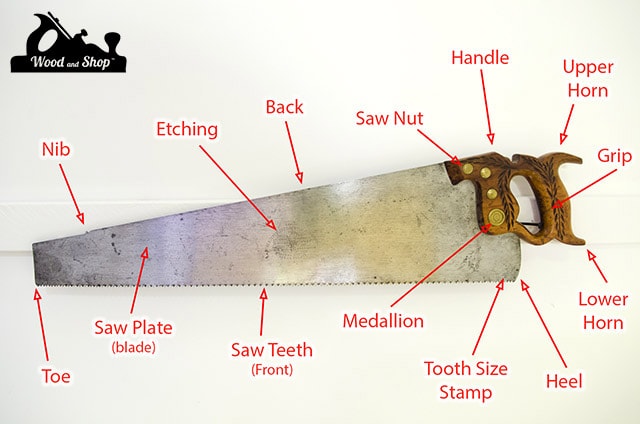

4. PARTS OF A HAND SAW

In the above diagram you will see the different parts of a traditional hand saw. Below you will see the parts of a traditional back saw. The obvious main difference between the two saw types is the saw’s stiff metal back:

What are the Best Hand Saw Brands?

I’m often asked, “what is the best hand saw brand?” Well, it’s hard to narrow down all the many vintage and modern saws to one best hand saw maker, but below I do share a list of old and new saw makers that made and make quality hand saws. The great news is that you can find fantastic old hand saws for as low as $5. And you can also spend several hundred dollars on a new or collectable vintage hand saw. And the purpose of this guide is to help you understand how to find the best handsaws for your hard earned money.

Aside from some certain quality modern saws, I would stay away from most cheap hand saws manufactured after World War II, especially if they are found at a hardware store. Yes, this is the same advice that I gave with hand planes. Tool quality really declined after WWII. Many cheap modern hand saws now have impulse hardened teeth, which are not possible to resharpen, thus making them disposable hand saws.

What brands of hand saws should you look for? Historically there were a lot of hand saw makers, because saws were easier to manufacture than hand planes. Here are some of the old and new quality saw makers (in alphabetical order). The blue links lead to eBay and other searches for those hand saw brands so you can compare different models.

***Note: some of the antique brands are not always available on Ebay, so keep checking back if you don’t see them in the search results.

***Note: the saws that are labeled as “desirable” refers to the demand for the saw, not necessarily the quality.

- A.F. Shotwell (really desirable)

- Adria (desirable – new saws)

- Atkins (E.C. Atkins & Co.)

- Belknap Blue Grass Colver (desirable)

- Colver Bros (desirable – Sheffield)

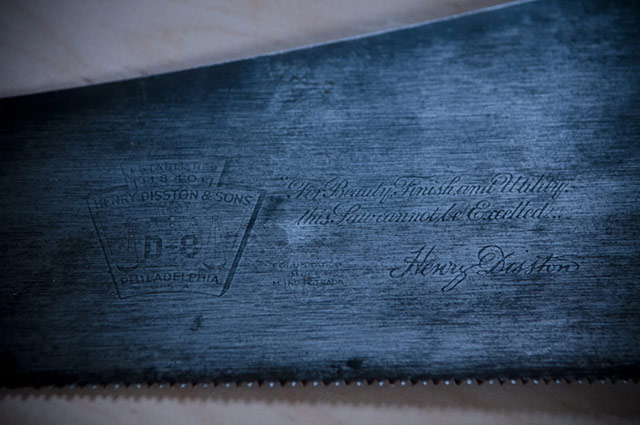

- Disston (Henry Disston & Sons – desirable)

- Drabble & Sanderson

- E.C. Atkins (desirable)

- E.C. Simmons Keen Kutter Fitchew

- Florip (great new saws)

- G.H. Buck (somewhat desirable)

- George H. Bishop (desirable)

- Harvey W. Peace (desirable)

- Hoole Staniforth & Co (desirable – Sheffield)

- J. Cranstone (somewhat desirable)

- Jackson (somewhat desirable)

- James Howarth (somewhat desirable)

- Kaye & Sons (desirable – Hull)

- Kenyon (desirable)

- Lie-Nielsen (really desirable – new saws)

- Mathieson Moulson Bros Pax (desirable)

- Richard Groves & Sons (really desirable)

- Richardson (somewhat desirable)

- Richardson Brothers (really desirable)

- Rob Cosman (great new saws)

- Sandvik (desirable)

- Simonds (desirable)

- Slack Sellars & Co (desirable – Sheffield)

- Smith (desirable)

- Sorby (somewhat desirable)

- Spear & Jackson (somewhat desirable)

- Taylor Brothers (desirable – Sheffield)

- Thomas Flinn (somewhat desirable)

- Thomas Tillotson & Co. (really desirable)

- Thomas Turner (really desirable)

- Tyzack Sons & Turner (desirable)

- Wenzloff & Sons (really desirable)

- Wheeler, Madden, & Clemson (desirable)

- Winchester (desirable)

- Woodrough & McParlin (desirable)

Sound overwhelming? Then just start off focusing on buying antique Disston saws. The Disston saws were manufactured by the millions and are the easiest to find, and most are of exceptional quality, especially the common models (see below). Remember to buy pre 1940’s era vintage hand saws. Here are some Ebay searches for wood saws. To ensure that you don’t over-pay, when you’re on Ebay click “sold” to see what they’ve been selling for, and to see which saw models are most desirable. It’s fun research:

- Disston Rip Dovetail Saws (8″-10″) No. 2 , No. 4, No. 5, etc.

- Disston No. 4 Rip Tenon Saws

- Disston No. 12 Cross Cut Carcass Saws (12″ blade…probably won’t say “carcass”)

- Disston No. 7 Hand Saws

- Disston No. 12 Hand Saws (very nice)

- Disston No. 16 Hand Saws (very nice)

- Disston D-8 Hand Saws (I love the optional thumb hole)

- Disston D100 Hand Saws

- Disston No. 112 Hand Saws

- Disston No. 7 Hand Saws

- This guy (woodnut4) beautifully repairs, sharpens, & sells amazing saws on ebay…very popular.

The Disstonian Institute is a fantastic free resource (compiled by Erik von Sneidern) for identifying Disston saw types, or models, their years, and quality level. I’ve spent quite a few hours on the Disstonian Institute website. Just don’t email Erik asking him to value your saw.

Refurbish and Sharpen Your Hand Saws

I use a lot of new hand saws, but I get really excited about antique hand saws. Finding and restoring antique hand saws can be extremely satisfying, affordable, and fairly simple when compared to other woodworking hand tools (like hand planes). I love the satisfaction I get from restoring neglected antique saws. Knowing that I am preserving and caring for some craftsman’s special tool makes me happy.

Here are two helpful articles & videos on my website to help you with rehabbing and sharpening hand saws:

Make Your Own Hand Saws

Another pastime that is growing in popularity is making your own hand saw. Hand saw parts and templates are readily available for anyone who wants to learn this historical skill, and create the best custom fitting hand saws. If you’d like to make your own hand saws, Tom Calisto, a hand saw making expert out of North Carolina, is one of the best teachers. He was featured here on The Woodwright’s Shop TV show:

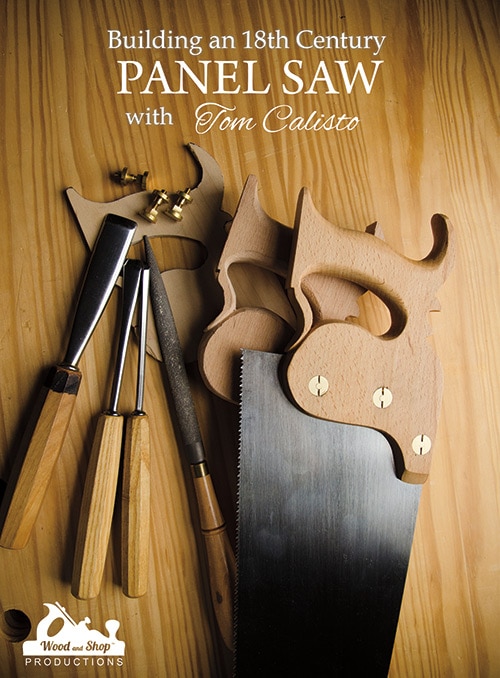

Tom currently teaches classes on building different types of wood saws at my woodworking school. He teaches one class on making an 18th century panel saw and another on making backsaws, where students can make a dovetail saw and a tenon saw of their own (see his classes here).

Tom and I also released a DVD & Digital Video on building an 18th Century Panel Saw, based on one found in the well-known antique Benjamin Seaton Tool Chest.

The hand saw building DVD was filmed to help even beginners build this lovely hand saw with very detailed step-by-step instructions and tutorials on how to use all the woodworking hand tools required for hand saw making. You can buy the panel saw video here.

1. Buying Panel Saws

As I mentioned earlier, I primarily use panel saws for rough cutting a board to an approximate dimension. And it’s technically possible to use just one panel saw for both rip cuts and crosscuts, but I recommend finding a dedicated rip panel saw and a dedicated crosscut panel saw so you can work efficiently and get cleaner cuts. If you look carefully you can buy two quality panel saws for a very low price. See some of the quality brands listed earlier in this article.

I own a couple dozen vintage panel saws, most of which I purchased for under $15 each (or was given for free). The price difference between a quality vintage panel saw and a quality new panel saw can be upwards of several hundred dollars. For this reason I only own vintage panel saws and panel saws that I’ve made myself. So I haven’t spent much time trying out new panel saws, nor have I recommended any yet. So this section will focus on vintage panel saws, until I try out more quality modern brands. If rehabbing & sharpening handsaws isn’t your thing, then looking at some new quality panel saws may be the way to go for you. I’ll test some of those saws in the future and will update this article. Alright, let’s jump into what you should look for when buying your two panel saws.

Buy a Rip-toothed Panel Saw

Rip panel saws make rip cuts along the length of the grain (“ripping”). Look for a rip panel saw between 4-7 ppi (“points per inch”). The ppi will usually be marked on the saw plate (can you see the number 5 on the above saw plate?). If not, you can use a ruler to see how many points you get in a one inch span. A 4 ppi rip hand saw will remove more wood, but may be more difficult to cut with.

Shorter hand saws (around 20-inches long) are officially called “panel saws” because they can fit in the panel of a large tool chest. But as I mentioned earlier I call all of these types of hand saws “panel saws” to avoid confusion among my students. You can call them “hand saws” or “panel saws”. The smaller panel saws usually have finer teeth and are more suited for finer cuts. Most normal panel saws run from 24-inches to 30-inches long. Try out different sizes to see which length you’re comfortable cutting with.

If you can initially afford to buy only one panel saw, then get a rip saw first. As I mentioned earlier, a rip panel saw can indeed make cross cuts, though it will be a bit messy. But it’s much more difficult to rip a long board with a cross-cut saw. It’ll take a very long time. Rip saws are also easier to learn to sharpen than crosscut saws, because you only have to file straight across the teeth, rather than at an angle. I own a good number of rip panel saws from different saw makers, but mostly Disston saws. They were the largest handsaw manufacturer. I’ve sharpened these rip saws in different ways for different jobs. But that’s a more complex topic that you can read about in my article on sharpening (read it here).

Some of the most desirable models of Disston saws are the Disston #16 hand saw, Disston #D-8 hand saw (with thumb holes is popular and useful), Disston #12 hand saw, among others. These pre-WWII models have excellent steel and nicely shaped handles.

Buy a Cross Cut Panel Saw

Cross-cut panel saws are used for cutting a board to a specified length, across the grain. As mentioned earlier, their teeth are usually smaller than a comparably sized rip saw, and the teeth are shaped like knives so they can cut cleanly across the wood fibers.

Cross-cut saw teeth are more difficult to sharpen than rip saw teeth, but I enjoy doing it. Look for cross cut hand saws with 7-9 ppi (points per inch). If your eyesight isn’t great, and you have a hard time identifying a crosscut saw by it’s tooth shape (little knives) then you can often assume that it’s a crosscut saw if it has smaller teeth. But the shape of the tooth is the best identifier if you can inspect it in person.

Other than the tooth size and shape, my advice for buying a crosscut panel saw is the same as I shared in the previous section.

Buy a Rip Dovetail Back Saw

“Back saws” are specifically designed for fine joinery work (they have a rigid steel or brass back to keep the blade stiff). Dovetail back saws are the smallest back saws (typically 8-10″) and are configured with fine rip-filed teeth (11-20 ppi) for cutting along the grain (think dovetails). Thinner blades (0.02″ ish) are preferred and I like the pistol grip handle because of my big hands (see above).

I have tried a good number of different models of antique and new dovetail saws, and own quite a few for my traditional woodworking school. While I’m sure that the very expensive dovetail saws (over $150) cut great, they’ve never been within my budget, so I’ll only be sharing recommendations on dovetail saws under that price point.

I own quite a few antique back saws, and they are all pretty great hand saws, like this No. 2 Disston brass back dovetail saw:

In fact, as long as the saw plate isn’t too thick (like the below Disston No. 2 “Manual Training School” dovetail saw that I bought years ago) most antique dovetail saws would be a safe bet, as long as they have a straight saw plate, aren’t missing any saw nuts, have an in-tact handle, and you don’t mind sharpening them. You can find links below to sources for good antique dovetail saws.

However, I have found that many of my students prefer to get cutting wood as soon as possible, and want to know what a super sharp dovetail saw feels like before spending time and money on rehabbing & sharpening antique hand saws. I can totally understand this, so I often share my recommendation on popular dovetail saw brands in the price range of $70 – $130. Here are a few of the popular dovetail saws within that price range:

Lie-Nielsen Dovetail Saw

I own quite a few Lie-Nielsen back saws, including several modern Lie-Nielsen dovetail saws, and really like them. The saw plate is thin, the teeth are shaped and sharpened fantastically, the saw is handsome with it’s brass back & figured maple handle, and the handle has acceptable comfort. They cost about $125 $150 plus shipping from Maine.

Veritas Dovetail Saw

The other very popular dovetail saw is made by Lee Valley / Veritas. I get asked all the time for my opinion on the Veritas dovetail saws, since they are significantly less expensive . I have owned several of them, and did some extensive comparison between them and the Lie-Nielsen dovetail saw. You can read my article comparing these dovetail saws here: Which Affordable Dovetail Saw is Best? Lie-Nielsen vs. Veritas.

While I like the price point (around $90 plus shipping), I find the handle wood to be pretty, and I applaud Lee Valley on coming up with original designs (Lie-Nielsen usually uses historical designs), I’m not a fan of their Veritas dovetail saw. I find the saw plate to be too thick, and the tooth shape and sharpness to be inferior to some other saw brands.

This makes the sawing a little harder and the kerf and accuracy slightly inferior. And I’m not a huge fan of the look of the molded plastic saw back, which of course is a secondary consideration. You can buy the Veritas dovetail saw here.

Florip Toolworks Dovetail Saws

The last dovetail saw that I tested in my shop, and with many students in my woodworking school, is the dovetail saw made by Florip Toolworks. I discovered Eric Florip after I wrote the article comparing Lie-Nielsen and Veritas dovetail saws, and the Florip dovetail saws have become a fan of his saws, both for the quality and price point. The 9-inch Florip dovetail saws start at $99 plus shipping (update: the price is now about $120…find them here) , have thin saw plates & great sharpening, and the handles are shaped in a similar way to the $200+ dovetail saws. The dovetail saw isn’t as aggressive or fast cutting as the Lie-Nielsen dovetail saw, but tends to cut a bit finer. Eric may have a longer lead time that Lie-Nielsen, which may be a factor for you if you want to get cutting wood ASAP. You can read my review on the Florip Dovetail saws here: Finally, the Best High-End and Affordable Dovetail Saw!

Gent Dovetail Saws

If you’re really on a tight budget then you can always buy a vintage dovetail back saw (they really are good if you spend time tuning them) or even a very inexpensive “gents” dovetail saw to start out with, like this one (I bought two for my sons for around $20), but make sure that you really tune it up. I don’t prefer how a Gents saw feels in the hand, but you may be willing to overlook it. Also, some come with teeth that I find to be too small (18-20 ppi).

Here’s a great video tutorial by Chris Gochnour (Fine Woodworking magazine) on tuning up an inexpensive gents dovetail saw.

This hand saw buying guide continues on the next page….