In this second part of Don Williams’ workshop tour, he shares his ingenious method for melting and refining raw beeswax for use in his famous beeswax wood finishes. If you missed the tour of Don’s timberframe workshop, watch it here.

While working as the Senior Furniture Conservator at the Smithsonian Institution, Don and his late colleague Mel Wachowiak patented what they believed to be the best furniture wax finish available (to be called “Mel’s Wax”), which is made up of beeswax, shellac wax, and other ingredients. It is best applied with a French “Polissoir”, which will be demonstrated in part 4.

He also uses the purified beeswax and shellac wax in his archival quality furniture lotion polish, which he used to preserve historical furniture for the United States government, including valuable furniture in the U.S. House and Senate buildings and the Smithsonian Museum. Like Mel’s Wax, this lotion polish can also be used as a finish all by itself, and Don will also demonstrate it’s use in the 4th video.

Both of these finishes should be available later this year. Don is also currently working on writing a book that will be called “The Historic Finisher’s Manual” and will include very large portions on incorporating beeswax, shellac wax, oil finishes, and spirit varnishes to help anyone who is interested in historic wood finishing. Add your name & email to this Google form if you want Don to contact you when all these products become available for sale.

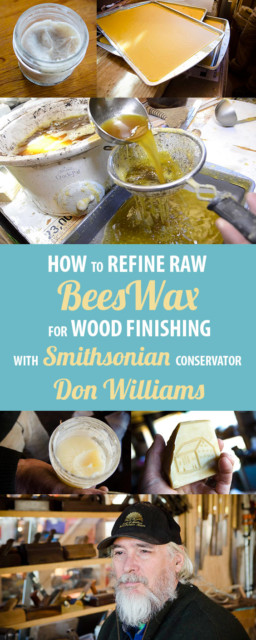

HOW TO REFINE BEESWAX FOR WOOD FINISHING

Don starts refining his beeswax by melting it in an old crockpot. To do this he first adds 2-inches of water to the crockpot and then adds the raw beeswax. The water will absorb out any water-soluble component of the raw beeswax (honey, etc). Once all the beeswax is melted, he uses a ladle to pour the melted wax through a strainer and onto baking sheets, to a depth of around 1-inch. The metal strainer will catch contaminants like honeybee body parts. The beeswax will separate from the water and water-soluble components (and honeybee parts) and will move to the top.

Once the beeswax has hardened, Don uses a knife to scrape the particulate matter (junk) off the bottom, then he repeats the process again twice (but with paper towels over the strainer) to further refine the beeswax until he gets beautifully pure beeswax as seen in this photo:

Don then uses the pure beeswax for his finishes or for selling in charming blocks with an illustration of his barn (he also sells his shellac wax in these blocks):

If you missed part 1 of the tour of Don Williams’ Barn Workshop, click here to go there.

This tour of Don’s workshop will continue in two following videos and articles. Don will show the workbench and hand tool area of his workshop (part 3), and finally he will show how to apply historical beeswax/shellac finishes using his historical handmade pollisoirs (part 4)! Click here to be notified when these videos and articles are released.

This workshop tour consists of four parts:

- Part 1: Don introduces his workshop and talks about how he moved the old barn across the country

- Part 2: Don will show how he refines raw beeswax for his historical finishes

- Part 3: He will show the workbench and hand tool area of his workshop

- Part 4: Finally he will show how to apply a historical beeswax/shellac finish using his historical handmade pollisoirs

I am a French polisher in UK, have been trying to get in touch with Don for a year or so, no luck at all but this beeswax video just popped up. I waterclean linseed oil, makes sense to do it with beeswax. Would like to perhaps buy his book and he might want to know something about my trade, was trained by proper polishers over 40 years ago.

Kind regards Jacob

Hello Jacob, it’s a pleasure having a French friend visiting my website! Have you tried contacting Don through his website? (http://donsbarn.com/contact/). If that doesn’t work, let me know and I’ll put you in touch. I’d love to see your work sometime.

Joshua Farnsworth

I watched my father clean bees wax as a kid and have a large lump in the shed I intend to make into polish to seal my workbench, so this has been a timely refresher… I recall seeing casting into a conical container. this has the advantage of the chunks settling into a much smaller (or at least concentrated) volume at the tip of the cone… I’m wondering though that if I intend to blend with turpentine and linseed oil,… Read more »

Love your website I’ve just discovered it. I am trying to learn french polishing. Watching Don refine Beeswax has now shown me how to, My cousin keeps Bees and has supplied me with Beeswax. I live in the UK and find American websites such as your so matter of fact and down to earth. Dons workshop looks great, packed to the roof with goodies

Thanks for the kind words Peter! Yeah, no philosophizing here…just practical advice. Where in the UK do you live? I used to live in Scotland.