Disclosure: WoodAndShop.com is supported by its audience. When you purchase through certain links on our site, we may earn a small affiliate commission, at no cost to you. Learn more.

Choosing a Woodworking Bench for Hand Tool Woodworking

By Joshua Farnsworth

In my opinion, a woodworking workbench is the most fundamental and most important tool in any workshop, let alone a traditional hand tool woodworking workshop. It’s difficult to build furniture by hand without a good sturdy woodworking bench to build on. Whether you’re planning to make your first traditional wooden workbench or planning to buy a workbench, it’s important to do a little research beforehand and get the features that will help you enjoy working with woodworking hand tools. Some woodworking bench features should be pretty important to everyone, and some features are more a matter of preference.

What Features to Look for in a Woodworking Bench?

When you are looking for your first woodworking bench (or woodworking workbench), which features are important to consider? Before jumping into the workbench guide, I’ll discuss some important features to look for in a woodworking bench, and define some of the confusing terms:

A. WORKBENCH STURDINESS AND STABILITY

One of the most important features to look for in a woodworking bench design is sturdiness and stability. Using a hand plane and sawing on a cheap and flimsy woodworking workbench will become frustrating very quickly as your workbench moves and shakes across the room. Sheer mass and weight are usually the solution for a sturdy woodworking bench, along with solid construction with good joinery. A workbench top of 3-4 inches thick will usually provide you with the mass you need. Some special woodworking bench designs (like the Moravian Workbench) provide sturdiness through design (splayed legs, mortise & tenons, etc.) which lets you get away with a less massive slab top and a smaller, portable workbench.

RELATED

All about Holdfasts for Workbenches

Which 20 Woodworking Hand Tools Should You Buy First?

How to Make Workbench Dogs, Dog Holes & Holdfast Holes

Which Hand Tools Do You Need for Building a Workbench?

10 Jaw-Dropping Woodworking Shop Tours

57 Page Moravian Workbench Plans Now for Sale

How to Make a Mortise and Tenon Joint with Woodworking Hand Tools

B. GOOD WORKING BENCH VISE

A woodworking bench vise is used to clamp your workpiece to the workbench so you can hand plane, saw, or shape it in any number of ways. Two traditional wooden workbench vises (or metal vises with wood to protect your workpiece), will be sufficient for a traditional woodworking bench. Traditional workbench vises more-or-less fit into two categories: (1) “Face Vises” which point toward the furniture maker on the face of the workbench, and (2) “Tail Vises” which are attached to the end of the workbench. The different types of workbench vises fall into these two categories. The type of woodworking bench vise that you choose is a matter of personal preference, so I would recommend that you try out different types of workbench vises, if possible, to see what you like the most. Most of the woodworking bench vises for my woodworking school were purchased from this company. Below is a little primer on traditional woodworking workbench vises.

~ WORKBENCH FACE VISES ~

“LEG VISE”

A leg vise is one of the most common traditional vises that you’ll find on an antique wooden workbench. This type of workbench vise is attached to a front leg (usually left side) and is tightened down with a wooden or metal screw and handle.

“SHOULDER VISE”

Shoulder vises were very common woodworking bench vises in continental Europe, and have a wide unobstructed opening that works great for cutting dovetails on wider boards. This is a favorite woodworking bench vise among woodworkers.

“FACE VISE”

A face vise (part of the category with the same name) is another very traditional type of wooden workbench vise. This vise is usually the same thickness as your workbench top and clamps against the top with either one or two screw arms. A drawback of this style of woodworking bench vise is that the screws get in the way of clamping a wide board. Also, you need to use a spacer to keep the workbench vise from “racking”. There have been some modern designs that have improved upon this design, like the Veritas Twin-Screw Vise, which uses a chain to equally tighten both sides of the vise.

“CAST IRON VISE”

These metal workbench vises came about during the mass production era of the industrial revolution. They are typically bolted to the bottom of a woodworking bench top and wood is usually added to the jaws to offer protection to a wooden work piece. The workbench vise can be mortised into the workbench top to give it a flush alignment. While this is a strong style of vise, it doesn’t have the traditional look that many woodworkers prefer when they build a classic style of wooden workbench.

“AUXILIARY VISES”

Auxiliary workbench vises can be clamped to your woodworking bench top, or even to a table top in your house (while you’re building a wooden workbench). This type of auxiliary vise with double-screws is often called a “Moxon Vise”, because the design was featured in Joseph Moxon’s classic 1703 English Woodworking book “Mechanic Exercises”. I love this style of vise for dovetailing large boards, because it has such a wide space between the wooden screws, and can be set on tall blocks to prevent back strain. Lake Erie Toolworks made the solid maple Moxon vise that I use (find it here).

~ WORKBENCH END VISES ~

“TAIL VISE”

A tail vise moves a bench dog to clamp a workpiece along the length of the wooden workbench top. This type of workbench vise also allows the woodworker to clamp a vertical piece in the opening. This type of woodworking bench vise is a bit more difficult to make, but it’s worth the effort.

“WAGON VISE”

A wagon vise is similar to a tail vise that moves forward and backward to clamp a workpiece along the length of the woodworking bench top, but rather than the entire enclosure moving, just the bench dog moves in an open recess. This is a simpler workbench vise to install than a tail workbench vise.

“END VISE”

An end vise (part of the category with the same name) is just like a face vise, but attached to the end of a wooden workbench. This type of workbench vise is useful because it allows you to tighten boards between bench dogs (like with tail vises and wagon vises), but also offers another area for dovetailing, etc.

Where to Buy Workbench Vise Hardware:

- This is where I got all the wooden screws for my leg vises: https://woodandshop.com/3e3x

- This is a great source for workbench hardware: https://woodandshop.com/82wj

- This is another great source for workbench hardware: https://woodandshop.com/ddyb

C. WORKBENCH LEGS FLUSH WITH THE TOP

A lot of cheaper commercial woodworking workbenches have popped up with a workbench top that overhangs the legs. This will lead to frustration because you won’t be able to clamp a long board or door in your face vise and clamp the other end of it against the legs. So just make sure that the legs are flush with the front of the woodworking bench top.

D. PROPER HEIGHT, LENGTH, & WIDTH

The dimensions of a traditional wooden workbench can be somewhat a matter of preference. But typically a woodworking bench top wider than around 24-inches is too wide (difficult to reach across). I really like having a longer workbench (8 feet long) because it allows me to woodwork on longer pieces of lumber, but my Portable Moravian Workbench is just over 6 feet long, and I’ve rarely felt that it’s too short. But most 6 foot workbenches (other than the Moravian workbench) are pretty flimsy. Just look at the space you have for a workbench and let that be your determining factor.

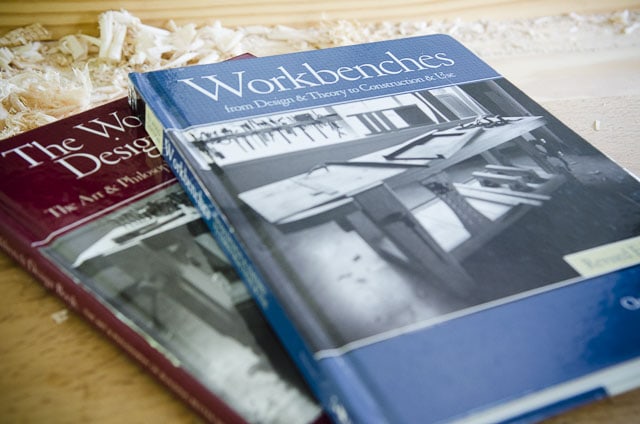

READ MORE ON DIY WORKBENCH DESIGN

Here are a few excellent wooden workbench books that I have read through quite a few times when deciding on which workbenches to build for my traditional woodworking school. They talk about various woodworking bench designs and features, and have plans for some really great wooden workbenches. You should buy these books, because they will really help you decide which features you want in a wooden workbench:

- “Workbenches: From Design And Theory To Construction And Use” by Christopher Schwarz

- “The Workbench Design Book: The Art & Philosophy of Building Better Benches” by Christopher Schwarz

- “The Workbench Book: A Craftsman’s Guide to Workbenches for Every Type of Woodworking” by Scott Landis

- “The Workbench: A Complete Guide to Creating Your Perfect Bench” by Lon Schleining

WOODEN WORKBENCH & TOOL STORAGE BUYER’S GUIDE

BUILD A DIY WORKBENCH (Option 1)

Building your own DIY workbench can certainly seem overwhelming for new woodworkers, but with the right assistance it can be an amazing project for beginners, and will even teach you many fundamentals about traditional hand tool woodworking or power tool woodworking. Below are a few quality DIY workbench design options that have recently become popular because of their fantastic features (and some helpful promotion by famous woodworkers). Disclaimer: these are only high quality DIY workbench design ideas, not flimsy 2×4 workbench design ideas.

Best Portable Workbench: the Portable Moravian Workbench

Two DIY Workbench Designs from Christopher Schwarz

Christopher Schwarz has done a great service to the woodworking community with his research and teachings on building traditional workbenches. Below are two DIY workbenches that he shares, the first a traditional French Roubo, and the second a simple & affordable two-day workbench.

DIY workbench 1: “Building a Slab Top Roubo workbench with Christopher Schwarz”

In this DIY workbench video Chris Schwarz gives a really great, quick overview of his Roubo workbench build.

DIY workbench 2: “Build a Sturdy Workbench in Two Days with Chris Schwarz”

This wooden workbench that Chris Schwarz came up with is a good option if you’re on a tight budget and you’re not concerned with having an attractive and traditional woodworking bench, but still want a DIY workbench that’s sturdy and quick to build. You can purchase his 4 part DIY workbench video course here.

Popular DIY Workbench Designs

There are so many different styles of classic workbenches (and hybrids of different styles), that I haven’t yet listed them all here yet (contact me here if you have a classic workbench style that you don’t see here, if you want to submit photos). For example, in addition to those listed above and below, some popular styles are Shaker workbenches, Holzapfel workbenches, Japanese workbenches, etc. Here are a few other DIY workbench styles that you should consider when building a woodworking bench for your workshop:

FRENCH ROUBO WORKBENCH

The Roubo Workbench is based on a design featured in an 18th century book by Frenchman André Jacob Roubo. Christopher Schwarz, in his above-mentioned books popularized this massive and sturdy wooden workbench. Many online DIY workbench tutorials have been created for building the Roubo workbench, but here are two that are pretty good.

EUROPEAN WORKBENCHES

Workbenches from mainland Europe encompass so many different styles, with many features overlapping throughout different regions. The Holzapfel workbench is one popular style of European woodworking bench. Frank Klausz helped to make the European style of wooden workbench more popular here in the United States. He learned to build furniture with woodworking hand tools on this type of workbench when he apprenticed with his father as a boy in his home country of Hungary. This type of wooden workbench often has a tail vise on one end and a shoulder vise on the other end, with a thick top. Here is a DIY workbench plan and step-by-step DIY workbench tutorial, by Keith Rucker, on how to build a version of this popular Frank Klausz workbench:

ENGLISH STYLE WORKBENCH

An English style wooden workbench typically has a thinner top, large double screw vise, and an apron with a lot of holes to insert a peg to hold long pieces of lumber. While this style of woodworking bench is sturdy, it does echo and vibrate a good deal due to it’s thin top. This woodworking bench is pretty affordable and quick to make due to it’s simpler construction and because it doesn’t have a thick workbench top. Here’s an article about this style of wooden workbench:

BUY A WOODEN WORKBENCH (Option 2)

Buying a wooden workbench is a valid option for woodworkers who either don’t have the time, or don’t feel that they have the skill to build their own DIY workbench.

If you’re new to woodworking, and have less time than money, then you may decide to buy your first woodworking bench. Don’t let anyone give you a hard time. It’s just fine to buy a wooden workbench. You can build one later on to earn your “woodworker’s right-of-passage”, if you want. However, there aren’t many good commercial wooden workbenches on the market for woodworkers who want to use woodworking hand tools. I’ve done quite a bit of research on this topic, because I wanted to have one commercially-built workbench in my school (the other 9 are shop-built workbenches). Earlier in this article I showed different characteristics to look for when choosing a wooden workbench design, and I used that criteria to narrow it down to a couple models, which I show below:

Sjoberg Workbench | Elite 2500 Beech Woodworking Bench (built in Sweden)

I spent a good deal of time researching different commercial workbenches, and eventually settled on a European style Sjobergs workbench, which is made in Sweden. This Sjobergs workbench is the only commercially-built workbench that I own. This woodworking bench is completely made out of quality European beech wood. European Beech is a very sturdy and stable hardwood, and is very plentiful in Europe. Most historical wooden hand planes were made out of beech, so you know it’s quality lumber. This is the Sjobergs workbench model that I purchased several years ago (there’s a video about this bench at this link too). You can also find Sjobergs workbench models here at Highland Woodworking.

My Sjobergs workbench is 8 feet long with a 4″ thick beech top and beech undercarriage. The wooden workbench weighs in at over 300 lbs, so it’s really sturdy. The face and end vises are convenient and powerful. The bench top is flush with the legs, which is great for hand planing large boards. This is virtually the only commercial woodworking bench that I was able to find with this feature.

This workbench does not have tool trays. I like workbench tool trays (some people despise them), but it is nice having a workbench in my woodworking school with so much surface area. There’s a wide, flat 24-inch wide surface of this Sjobergs workbench. The woodworking bench came with 1-inch dog holes and metal bench dogs. I also drilled my own 3/4-inch holes for holdfasts (see my section below on choosing holdfasts). I actually purchased my workbench with an optional under cabinet, which is handy but not vital. It does add extra weight, stability, rigidity, and storage. All good things for a wooden workbench.

German Hofmann & Hammer Wooden Workbench

This large European-style “Hofmann & Hammer Premium German Workbench” is the workbench that Roy Underhill uses for his students at his Woodwright’s School: see it here at Highland Woodworking. I’ve used these workbenches quite a few times and really like the traditional-style vises.

It’s not as heavy or as rigid as the Sjobergs workbench mentioned above, but you can add extra weight by placing bricks underneath the workbench undercarriage to weight it down. And it’s a lot less expensive than the Sjobergs bench, at around $1,500 (plus freight shipping). That’s not a bad deal. I definitely prefer the Sjobergs workbench, but if your budget is tight, then this woodworking bench might work well for you.

Not many online retailers sell workbenches (because of the difficulty in shipping them), but Highland Woodworking has a good selection of traditional woodworking workbenches: here.

Buy Workbenches at eBay

You can also find quite a few workbenches to purchase (new and used) on eBay. Shipping is surprisingly affordable on some of these workbenches on eBay. Here are some workbenches on eBay. Just make sure that it’s heavy and sturdy enough for your intended use. You may see a lot of flimsy wooden workbenches on Ebay.

Buy Workbenches at Amazon.com

Amazon now has a descent selection of wooden workbenches. Liek with Ebay, many of the woodworking benches on Amazon are flimsy, so make sure you use my above-advise to help you in choosing a good workbench. Here are some workbenches and workbench accessories at Amazon.

Buy Workbenches Locally

Every once in awhile I see nice antique workbenches listed for sale on Craigslist, Facebook Marketplace, or other free classified ad websites. Yard sales and estate sales are also an option for finding a woodworking workbench. This is a nice option because you can go “test drive” the workbench before you buy it. However, be aware that most people that sell these workbenches locally are thinking of selling it as expensive décor for someone’s fancy house, so the price may be too high.

Page: 1 | 2

This workbench buying guide continues on the next page….